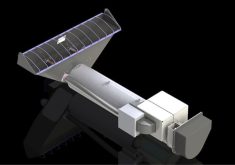

The Troo Corp., a web-based mapping and tracking company, released a universally adaptable, Canadian-designed yield monitor in Ontario this year.

Called FarmTRX, the company is touting the technology as cost-effective, accurate, and easy-to-use yield mapping system that can be retrofitted onto combines of all colours, size, and vintage.

Why it matters: Yield monitoring technology is not new, but cost and proprietary systems have limited adoption. The Troo Corporation says its FarmTRX system was designed to remedy such challenges.

Read Also

Agco settles legal dispute with TAFE

Agco and Tractors and Farm Equipment (TAFE) from India announced July 1 that they had settled their legal dispute, which began in 2024 over local ownership of the Massey Ferguson brand name and other concerns.

Mark Hammer, vice-president of sales and development for Troo Corp., says the technology was developed by Saskatchewan farmers as a substantially cheaper alternative to the yield monitoring systems built into existing combines.

The $1,849 system consists of a yield monitor and sensors, wiring, and GPS antenna.

Users in the cab connect the system to whatever device they have available, such as a smartphone or tablet.

The FarmTRX system’s ability to allow farmers to incorporate their own in-cab displays is one reason why the unit is cheaper than built-in yield mapping systems offered by equipment manufacturers, says Hammer.

“We’re not going to develop a better display than an iPad. There has been a lot of advancement in the technology,” he says. “If we had developed this 10 years ago it would have been $15,000.”

The FarmTRX system can work with any combine with a clean grain elevator, just like a smartphone can be used in any car given the right setup.

“The oldest combine it’s in is a 1969 John Deere 105, and the newest is a 2019 Case 9240. If it has 12-volt power the system will work,” Hammer says. “You can put this on your mid-80s combine and leapfrog the manufacturer’s systems. Its modern and doesn’t need to tie in, it just requires power.”

Installation takes between one to four hours, though some combines, such as John Deere, can take longer if access to the grain elevator is constrained by other parts.

“Case and New Holland are easier … it’s just drilling a few holes into the elevator. The rest is just running wires,” Hammer says.

Colin Elgie, a farmer and agronomist with Sylvite Agri-Services Ltd. in Chatham-Kent, says he and his brother decided to purchase and test a FarmTRX system for their own combine before deciding to become a regional dealer for the product.

“We added it to a John Deere 9500. It’s an older combine for sure. Probably 25 or 30 years old now,” says Elgie. “Basically, we were using ourselves as guinea pigs and trying it without having to spend a pile of money.”

“To get a yield monitor from the dealer would have been $10,000 to $15,000.”

FarmTRX requires calibration, because it measures volumetric flow rather than grain mass. However, Hammer says only one calibration per crop, per season is required. It’s also possible to back-calculate and correct mistakes.

“The initial system setup is running the thresher at full speed and with a clean grain elevator so the sensors are measuring how thick the paddles are, which are different on each individual combine. We calculate the height of the grain on each paddle,” Hammer says. “You can then adjust based on speed and header types.”

Elgie says installation was easy. The most significant hiccup they had after installation was figuring out how to navigate the “relatively simplified app system” accompanying the hardware.

“Some ways to get to certain spots in the app weren’t exactly obvious. But once we figured it out, it’s pretty easy to help others walk through those issues.”

FarmTRX was designed to help growers interpret yield data easily as well, according to Hammer. This is done via the program itself, which automatically cleans the data before generating yield maps. Purchasers of a FarmTRX system can access this aspect of the technology for free for the first year, but an annual subscription is required afterward.

Elgie says he and his brother have made use of the full FarmTRX suite of services.

“It does a good job cleaning up the data so we don’t have to spend the time, and works very easy and accurately from what we found.”

However, farmers can manually process or export data, as well as use the real-time app, without a subscription. If, for instance, they want their agronomist to generate a map, they could do so.

“We’re not trying to recreate farm management tools …. It’s possible to export data into Ag-Leader Advance, or into Climate FieldView, for example. It’s very easy to get into other systems,” says Hammer.

Elgie and his Sylvite colleagues originally became interested in selling the FarmTRX system because they saw it as a good way to support their customers who do not already have yield monitoring systems.