Where do you start with data management on crop farms?

Three farmers who use data extensively say to start with what you can manage and make sure that the system is set up from the start to supply quality data into whatever system you choose to manage it.

Why it matters: Sensors and better recording equipment mean greater opportunity to gather data on farms. The challenge is creating data that is useful and can make for better decisions.

Steve Twynstra says he started with a yield monitor on his combine in 1994. Autosteer and section control have also been influential on his farm. At the Judge Farm, where Derek Hill is operations supervisor, he says they have had highs and lows in their use of data in their cropping operations, but that a yield monitor that can pinpoint yield changes than can really be analyzed, has made a difference for their farm. Hill uses RTK – the most precise level of auto-guidance and that makes for more precise information

Read Also

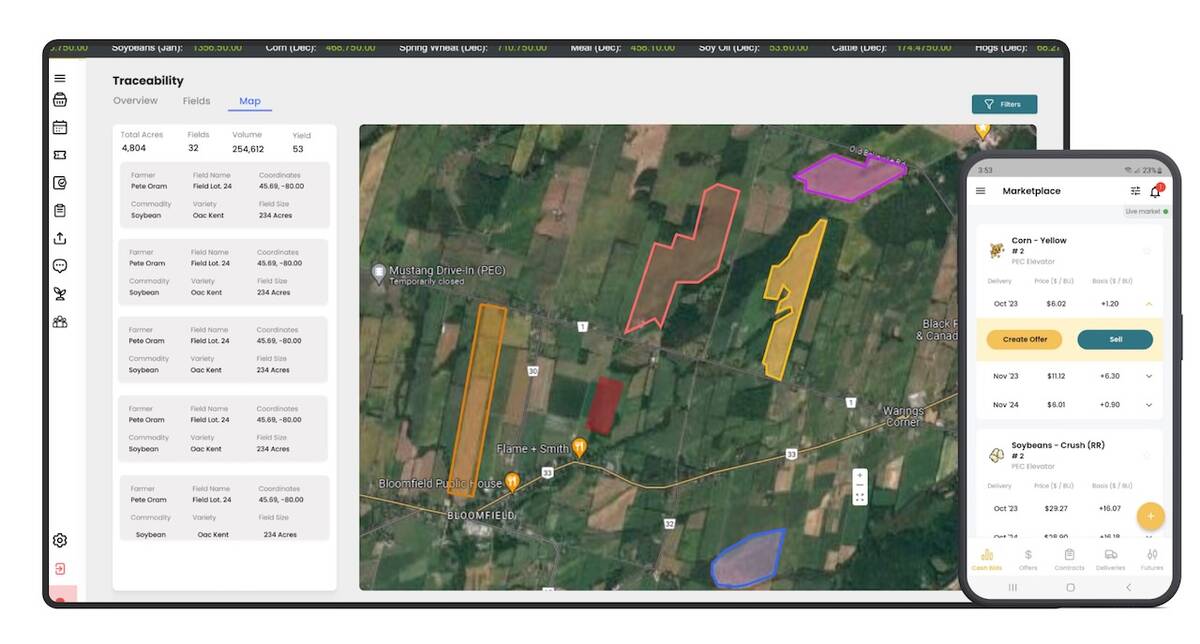

Ontario company Grain Discovery acquired by DTN

Grain Discovery, an Ontario comapny that creates software for the grain value chain, has been acquired by DTN.

Joining Twynstra and Hill on a panel at the London Farm Show was Scott Fife, who says he has always been keen on digital agronomy. He started down the path to more mapping and data collection when he was working for DuPont Pioneer in research, based in Chatham, while his family farmed in Stormont and Dundas counties. Being able to access maps meant not having to pepper his father with questions.

The three were part of a panel put on by DuPont Pioneer on managing data on farms.

Twnystra, who has managed data such as inputs on individual fields for years on Excel spreadsheets on his Ailsa Craig-area farm, says he hopes he can eventually get to “being able to manage our fields financially, down to pennies per acre versus dollars per acre.”

He’s now using the Granular software platform, now owned by DuPont Pioneer, to tie his agronomic data to his financial data.

Hill uses Climate FieldView and Fife, DuPont Pioneer’s Encirca platform.

Here’s how the farmers answered questions on managing data:

Q: How do you avoid poor quality data – the garbage in, garbage out syndrome?

Twynstra: He has used section control and says making sure everything is calibrated is important. “It’s embarrassing when you see a clutch shut off three feet too early or three feet too late,” referring to section control on sprayers or planters.

He recommends making sure to update software. Make sure to back up data, and not just after the combine is parked in November. He had a laptop stolen with data on it that wasn’t backed up and that’s why he appreciates cloud-based services.

Hill: Make sure you name fields and set boundaries properly at the start of use. Take the time to calibrate equipment. “It will pay back later,” he says.

Fife: The Fifes run three combines for the large amount of custom work they do. They all get calibrated, and he says that should be multiple times, especially in a corn crop.

Q: How do you manage workflow with technology?

Twynstra: Efficiency gains are realized when you see what time you spend on each field. Understanding how worker and equipment time is used will be a competitive advantage in the future, he says. Granular allows him to track how much time is spent on each field operation.

Hill: Managing data doesn’t save time, but the ability to better plan, should save time down the road. The ability to share the data with anyone – someone else on the farm, or an agronomist for example – on any connected device, can help.

Fife: “I can’t say technology saves me time. There’s just a lot I learn that I wouldn’t know otherwise.” He can learn more in the same amount of time, he says.

Q: What other tools are needed?

Twynstra: His operation focused on identity preserved soybeans and pedigreed seed production, so being able to measure the value of some of those crops on the go would be an advantage. He mentioned measuring protein on the combine. He says varying seed and nutrients is now fairly easy, but there need to be more data relating to seed. He challenged seed companies to have better data, such as on white mould in soybeans and how it is affected by variable rate planting and fertilizer application.

Hill: He could see more multi-variety and hybrid planting – moving beyond just varying population.

Fife: Moving forward with variable rate planting is one of his next steps. “I do see a benefit to that in both corn and soybeans.” He also says varying nitrogen according to plant population will have a benefit.