A German company tested its electric desiccation system on Canadian farms this year as it works to bring weed control using electricity to large-scale farms.

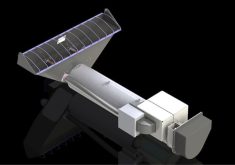

Crop.zone is unique in that it combines an application of liquid to the plant at the front of the tractor and an electric shock at the back, which helps with burndown of crops without the use of herbicides.

Read Also

Evolution of European equipment manufacturers runs deep

A look at how Lemken and Väderstad have evolved from their traditional offerings of tillage equipment to include planting and seeding equipment in their lineups.

Why it matters: More food companies and other buyers want to source grains and oilseeds with less chemical application, particularly at harvest.

Dirk Vandenhirtz, CEO and founder of the company, says that electricity is the mode of action for the product, but it uses no chemicals.

Food companies like PepsiCo are looking for crops with reduced pesticide application, especially the desiccation application that kills crops to make harvest easier.

“They tell us that they have an increasing need for residue-free crops like oats and chickpeas,” says Vandenhirtz. “They are trying to source them, so there is a market” for products with lower pesticide applications. High values for crops with lower residues could be a good business model for Canadian farmers, says Vandenhirtz.

The concept of using electricity to kill plants goes back more than 100 years, he added. The challenge is the amount of energy needed to kill a plant.

“You have a high level of resistance at the surface of the leaf.”

The company developed a conductive liquid that is applied just before the electricity. It can be thought of like a surfactant that is used to make a herbicide more effective.

“That lowers the necessary energy by a factor of 10,” says Vandenhirtz, and that helps the company manage wider application booms with less electricity.

Crop.zone has been working in the area of Outlook, Sask. Darrell Bailey, the company’s head of business development for North America, says it has been tested on potato farms in the area to provide a chemical-free desiccation option. The company is working with the Prairie Agricultural Machinery Institute to make sure its machine adheres to North American guidelines.

The company won a silver in the innovation program at Agritechnica in Germany in November for the next stage of its product development.

The company has nine and 12 metre (30 and 40 foot) options, with different boom options for potatoes, grass and cover crops and standing crops.

Those widths “don’t bring a smile to Canadian farmers”, says Vandenhirtz, because Canadian sprayers are usually much larger.

It is working with John Deere to develop a 24 metre (80 foot) unit that fits onto existing self-propelled or other sprayers. The sprayers would deliver the Volt Fuel liquid and then a boom unit has attachments that fit between rows so in-crop weeds can be treated.

John Deere helps bring section control and row alignment camera technology to the project.

Boom width is needed to treat a lot of acres in a short time. The other need is speed. Vandenhirtz says the Crop.zone unit will only work up to at about eight kilometres per hour at this point.

However the long-term goal is parity with sprayer technology.

“We are improving that step by step. Our goal with our development team is to make that system as efficient as a sprayer,” Vandenhirtz says.

The company expects to have its 80-foot systems on the ground next year in testing with farmers.