Glacier FarmMedia – The new Horsch Leeb sprayer made its Canadian debut July 19.

Controlled droplets close to the crop reduce drift and put the product on the plants where it does the most good, whether for insects, disease or weeds. The sprayer is engineered to do just that – put the nozzles closer to the targets.

Three hundred farmers attended the field day to check out nearly 40 new Horsch and Claas implements and talk iron in person with Michael Horsch, president of the company that bears his name, and Eric Raby, president of Claas North America.

Read Also

Canada to have increased presence at Agritechnica 2025

Interest in diversifying trade markets is taking more Canadian manufacturers to Agritechnica 2025, the world’s largest machinery show.

The event, named Down 2 Earth, was hosted by genAg at the Kehler Oak Ridge Farm west of Carman, Man.

In an interview, Horsch said the marketplace is full of companies building high clearance sprayers but the Horsch family has been selling high tech sprayers to European farmers for nearly 40 years. He said it’s time sprayers took a giant step into the future.

Chemical restrictions in Europe are imposing strict regulation on agricultural chemicals and penalties are severe for farmers who fail to meet the criteria. Horsch said Europe plans to cut chemical use by 40 per cent.

Knowing that, he concluded that the world needs better sprayers for more prudent applications. Better field management will reduce chemical use, but in the end, the issue demands better application technology.

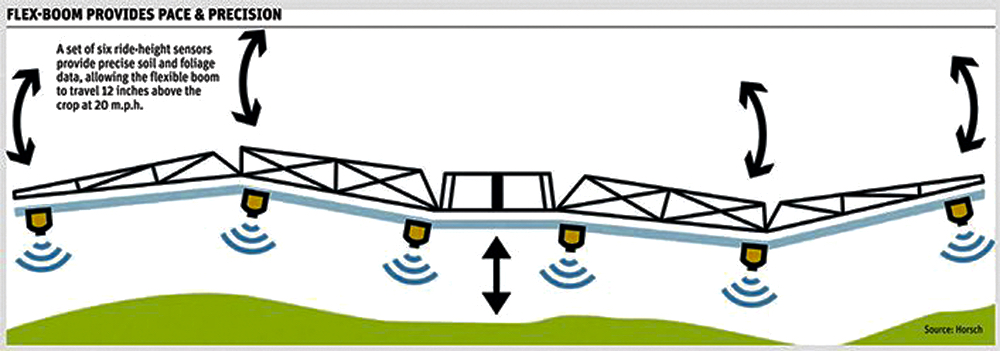

“This is why we came up with automatic boom levelling, so we can get very close to the crop.

“We can adjust for droplet size, provide better penetration, thus apply less chemical volume. It’s not only what you spray, it’s also a matter of how you spray.

“To run your 133-foot boom 10 inches above the crop without damaging plants requires highly complex engineering that nobody else can match. Before our competitors get to where we are today, they first have to get to where our architecture was 10 years ago. And by then we’ll have jumped another decade ahead,” said Horsch.

Putting the boom closer to the crop allows finer spray particles to uniformly hit weeds, insects and diseases before the spray either drifts or evaporates.

According to Horsch, the Boom Pro Plus control allows boom sections to move independently, contouring over knolls while lifting on the side of a valley, keeping each section close to the crop even at normal spraying speeds. Nozzles are available on 20-inch or 10-inch spacing.

Sensitive proportionate control with six sensors makes individual boom sections adapt smoothly to the terrain contours.

Maximum boom width is 133 feet. A 176-foot boom is expected to be available next spring.

Horsch said competitors’ sprayers are between two and four tonnes heavier than the new machine. That weight discrepancy can be applied to a bigger payload. At 2,113 U.S. gallons, the stainless-steel tank is the largest on the market.

The lower weight can also be applied to reduce compaction, burn less fuel, lower power requirements and spend less time stuck in mud.

“There’s one other factor that’s just as important in keeping the sprayer going in mud and that’s weight distribution. Empty or full, it has an almost perfect 50-50 weight distribution front-rear. With a machine that’s heavier at one end, empty or full, that’s the end that will go down. Equal weight distribution keeps you moving.”

The machine can climb a 50 per cent incline. Its high-power gear feature shows its strength at low speed with extreme slopes.

When on the verge of getting stuck, this provides a power reserve to keep moving. Top speed on the road is 33 mph, while maximum spraying speed in the field is 20 mph.

The sprayer has clearance of 6.5 feet and track width up to 13 feet. Tires up to 29.5 inches wide are available. All-wheel steering and the central tube frame allows for a turning radius of 11 feet. Power comes from a 408 CID six-cylinder Fiat Power Train turbo engine with a common-rail system putting out 310 horsepower.

“A sprayer is a complicated device. It requires diligent backup. In North America we sometimes have a challenge finding the right dealer,” said Horsch. “So, we start them out selling more basic equipment. Once we’ve seen they are fully competent, like the genAg people here today, then we offer them the opportunity to take on sprayers.”

– This article was originally published at The Western Producer.