Glacier FarmMedia – Krone and Lemken teamed up to build a robotic tractor and implements designed to help the companies keep pace with the autonomous revolution expected to sweep the agricultural sector.

Combined Powers is the name of the joint project. Yves Desjardins of Lemken said there are multiple reasons it made sense for the companies to work together. Both are mid-sized, family-owned German companies that have worked together in the past.

“There is no overlapping of the products, and we have all over the world some common dealers and importers partners. So, we regularly communicate and work with each other,” Desjardins said.

Read Also

Could John Deere have imagined what his company has become today?

Let’s ask the company’s own archivist: would John Deere, the man, be surprised to learn his eponymous field plow company is now a global corporation with around US$30 billion in annual turnover?

The tractor is cab-less with a diesel-electric drive powered by a Rolls Royce Power Systems MTU four-cylinder, 230 horsepower diesel engine, capable of producing up to 170 kilowatts of electricity. The engine is based on a Mercedes Benz design found in a wide variety of agricultural applications.

The frame, driveline and software have been designed for automated Krone and Lemken forage harvesting and tillage attachments.

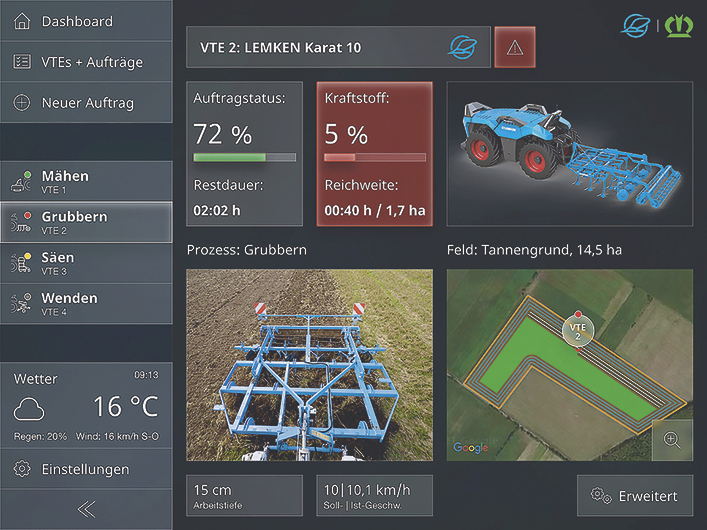

The implements and the drive unit, which Combined Powers calls an autonomous process unit, act as one integrated system.

Multiple sensors and artificial intelligence are used to detect obstacles and plan the machine’s path, and ISOBUS is used to communicate between the drive unit and the attached implement.

Desjardins said Combined Powers is an extension of the automation development already achieved at each company, and both companies already have automated systems in their equipment line-ups.

Krone’s forage harvesters have an operator assist system that uses a photo-optical sensor in the middle of the corn header to measure the maturity of the plant and automatically adjust the length of cut. It also automatically matches the speed to the crop stand and yields.

Lemken is also adding sensors and collecting information from its tillage and planting platforms.

A cultivator Lemken developed for the Combined Powers system can detect tillage depth and tell whether the cultivator is plugging with trash.

“One camera is to avoid the addition of too much accumulation of earth and vegetation trash, and one sensor is there to calculate the distance to the ground and to measure the working depth. Another camera is for checking soil crumbling,” Desjardins said.

“The cultivator is changing according to the contour of the field where you are working.”

He said Lemken’s seed drills already send information to tractors through the ISOBUS connection.

When it comes to agricultural equipment, Desjardins said there are two major categories of automation.

The first focuses on control of the robot in terms of where it moves in the environment, with a focus on the distance between it and objects and how to avoid them.

“On the other side you have the process control. We have some sensors and cameras, and they are more focused on the machine’s (work).”

Operators of the robotic platform will control and monitor it from a mobile device used to assign joAbs and receive reports via a communication module and a data exchange hub.

“If the machine detects an obstacle, it has a possibility to change the trajectory and to respect a certain distance to the obstacle,” Desjardins said.

The technology developed at Combined Powers will help both Krone and Lemken improve the automation in products it builds for use with a traditional tractor and operator setup.

Last year, Combined Powers used the robotic platform to cultivate, plow, sow, mow and rake.

It has not said when or if the platform will be commercially available.

– This article was originally published at The Western Producer.