A key piece of technology important to the success of biogas digesters in Europe is now available in Canada.

Advance Tank Production Ltd., has built a rapid loading and unloading tanker that makes moving manure around quicker and more efficient.

Why it matters: Biogas digester numbers are growing in Ontario, but some infrastructure still isn’t available on the market for more complex community systems.

Read Also

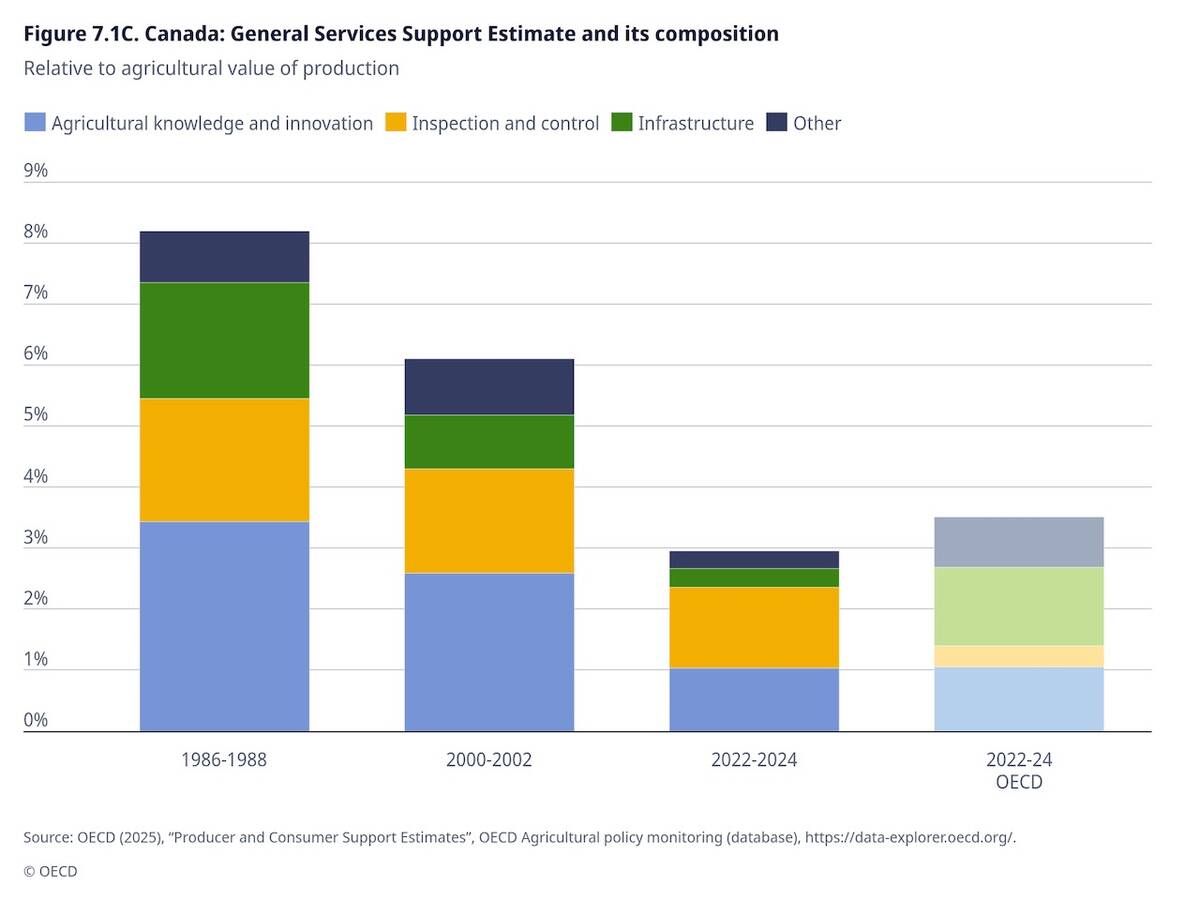

OECD lauds Canada’s low farm subsidies, criticizes supply management

The Organization for Economic Co-operation and Development lauded Canada’s low farm subsidies, criticized supply management in its global survey of farm support programs.

The tank was made by the Saskatchewan company, a division of Advance Engineered Products, and won the top award in the equipment category in the 2024 Ag In Motion innovation competition.

Biogas systems in Europe increasingly are centralized or community-based, meaning that farmers move their manure to another farm or facility where it is put through a biogas digester. The manure is processed by the digester, with nutrients concentrated and methane captured either for conversion into electricity or used as natural gas on the farm or in a natural gas pipeline system. The digestate is then moved back to the farm where it is spread on land as a high-value fertilizer, or separate from liquid with a screw press and dried for use as bedding.

There are few biogas digesters in western Canada, but several dozen operating, mostly on individual farms, in Ontario. There are also many biogas digesters in the United States.

Mike Frombach, from Advance, says that with greater emphasis on managing nutrients effectively, there much more interest in biogas digesters.

Advance partnered with VM Tarm, a Danish company, which provided the back end of the pumping system. Denmark is a world leader with more than 100 biodigester systems installed. VM Tarm provides pumping systems and transportation tanks, including for the biogas sector.

“There are quite a few biogas companies from Denmark coming into the Canadian and the United States market,” says Frombach.

A barrier to getting to a profitable scale for a biogas digester is the cost of moving manure. The Advance Tank Production system aims to help solve that problem.

Large digesters could use six of the trailers in order to keep their operations running, says Frombach.

The trailers could also make sense for individual farms which are digesting manure from other farms.

The system was on display at Ag In Motion where the company demonstrated the rapid speed of loading and unloading liquids from the three-pump tank system. An crane arm stretches out from the tank and can be raised or lowered into the source or destination for the slurry.

The tanker will unload at about 15,500 litres of water per minute and loads at about 12,500 litres per minute. The operation of the unit is set up so that the driver doesn’t have to leave the cab, which can be appreciated in extreme weather, says Frombach, but it also can help alleviate biosecurity risk, if the driver visits multiple farms.

Frombach says there are other uses for the trailer including helping to manage floods and fighting fires. Adding a four-inch nozzle onto the end of the hose enables the system to spray water from 160 to 170 feet.