Jake Kraayenbrink is passionate about soil health — so much so that he’s spent the better part of the past 15 years developing an innovative tire deflation system that helps farmers reduce soil compaction risks from heavy equipment.

It’s on the market today in Canada, Europe, the U.K. and New Zealand under the AgriBrink brand.

Why it matters: Farmer-developed innovations can help with farm operations, but also grow into international businesses.

Read Also

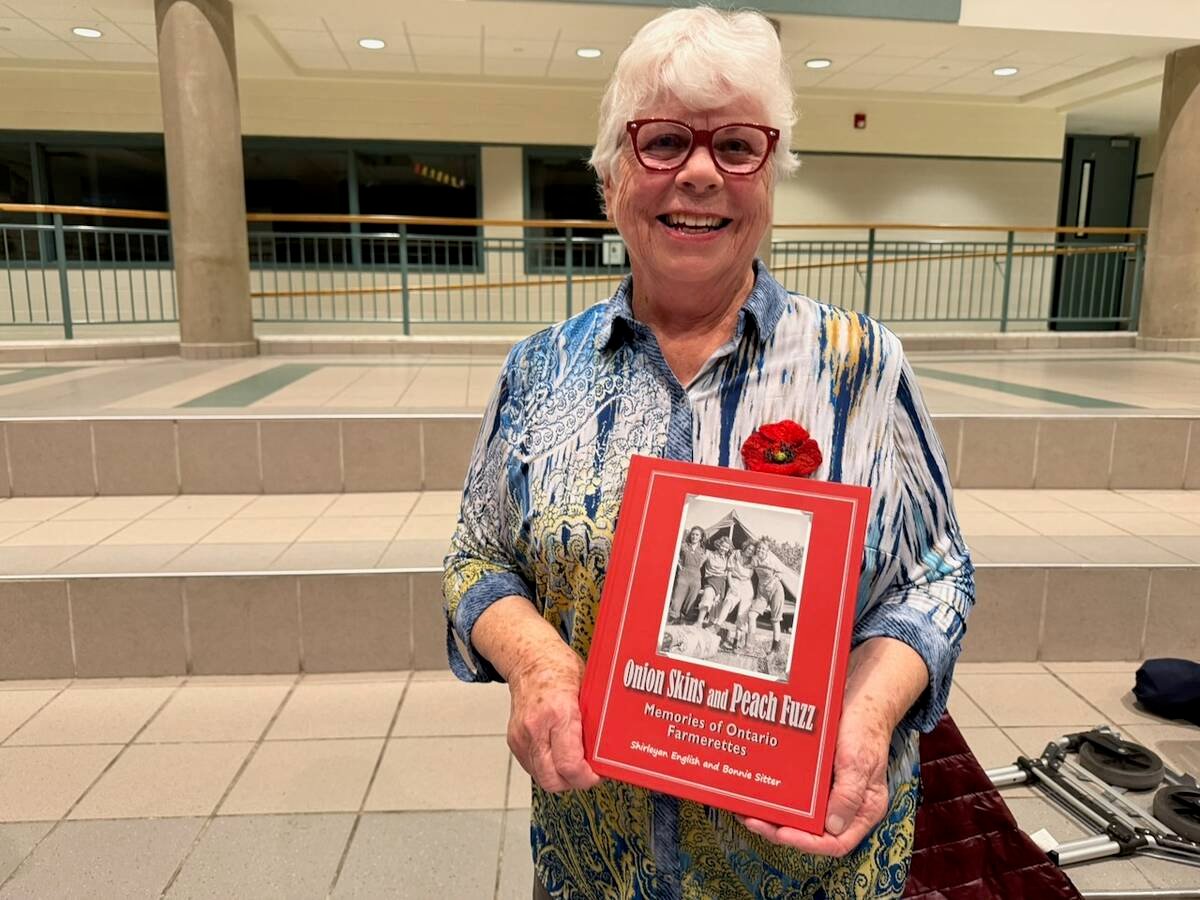

Women who fed a nation

More than 40,000 young women supported the war effort between the 1940s and early 1950s, helping grow and harvest crops amid labour shortages. They were called Farmerettes.

It was another innovation, however, that won Kraayenbrink the 2023 Don Hill Legacy Award for on-farm innovation from the Ontario Soil and Crop Improvement Association (OSCIA). He developed a modified manure tanker that lets farmers seed cover crops together with a manure application into a standing corn crop.

Like most pork producers, the Kraayenbrinks grew quite a bit of corn on their Drayton-area hog farm. Manure is applied and incorporated in late fall or early spring, leaving no time to plant a cover crop after fall corn harvest.

That led Kraayenbrink to modify a Nuhn 5,000-gallon manure tanker that injects manure as a side-dress into standing corn at the four to eight-leaf stage while simultaneously broadcasting cover crop seed.

“It’s an honour for us to receive this award. I enjoy fields and I enjoy crops; it’s amazing how the soils are created and all the microorganisms in there,” Kraayenbrink says. “To receive this is really quite a big deal.”

Kraayenbrink’s side career as an innovator began in 2009, when he first started trying to solve soil compaction issues caused by heavy tankers applying liquid manure from his pigs onto the land. Early support from Ontario Pork and the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) helped Kraayenbrink get started.

His first functioning prototype tire deflation system took much too long to deflate, however, so with help from a local engineer and a truck mechanic, he built his first working system from scratch using components from the trucking industry.

“We were able to get from 35 lbs (of tire pressure) to 12 lbs in 20 seconds, so we were pretty thrilled with that,” he says.

“We decided to build our system from the farmer’s perspective. We had no preconceived notions, we just knew we needed it to be very fast and for people to always be able to get parts no matter where they were.”

That first system also included a manual override that allows an operator to continue even if the electronics fail, and a black box that records driving speed, tire pressure and location.

Things were tough in the hog industry at the time, so on the advice of an OMAFRA engineer, Kraayenbrink began attending farm shows in hopes of marketing his innovation.

A chance encounter with a visiting Danish delegation at Canada’s Outdoor Farm Show planted the seed of international market opportunities and through Bioenterprise Canada, Kraayenbrink secured a spot on a Canadian delegation visiting Denmark in 2015.

“A guy in Denmark remembered me from a previous trip and he bought one of my systems, so I came home with an AgriBrink system going into Denmark,” recalls Kraayenbrink.

Research and development continued and the system was featured at an Ontario soil compaction event in 2017 where it garnered considerable interest.

A significant breakthrough came in 2021, though, when a tire company in the Netherlands looking for a deflation system heard about AgriBrink from a relative of the Kraayenbrink family and placed an order for 10 systems.

“We hoped they would sell eight but they sold 80 in 2021; that was huge,” Kraayenbrink says, adding that despite significant COVID restrictions in 2021, he and his wife Betty were lucky enough to travel to Europe and the UK that year for key face-to-face meetings with suppliers and distributors.

Overall, interest in compaction issues is growing and although manufacturing of AgriBrink continues to be centred in Drayton, the Kraayenbrink family has recently relocated to Iowa to build its operations for the U.S. market.

“The biggest helpers were my family who all put money into this and took care of everything when I travelled so much,” he says.

“AgriBrink was a passion we had, and a lot of people deserve credit, I just happened to be the one to do it.”