A weed destruction system, to mount on the rear of combines, that uses a specific spectrum of light, is being developed through a partnership between Redekop and Global Neighbor Inc.

It will work on smaller combines compared to Redekop’s physical seed destructor system.

“With this light technology it can be 10 to 15 horsepower to run material through it,” Thiessen says. “So it’s significantly less. That amount of horsepower is pretty easy to incorporate into most of those smaller Class 6 or 7 combines.”

Read Also

Canada to have increased presence at Agritechnica 2025

Interest in diversifying trade markets is taking more Canadian manufacturers to Agritechnica 2025, the world’s largest machinery show.

Thiessen says the company often has to tell producers with those smaller machines its original SCU just won’t work for them, because of that high horsepower draw.

Redekop’s Seed Control Unit (SCU), pulverizes seeds coming out of the back of a combine, but it can only be used on Class 8 and larger combines because of its relatively high horsepower demand.

“We say it’s in that 65- to 80-horsepower range,” says Trevor Thiessen, CEO and owner of Redekop of the SCU. “Ours is like a blunt-force impact mill where we’re trying to hit the seeds.”

However, a lot of farms are still using older, smaller combines that can’t spare that much muscle.

“If you look at the North American market there’s something like 50,000 John Deere STS combines still running out there,” he adds.

So now the Saskatoon-area company has announced it’s working on an alternative seed destruction concept, in partnership with U.S-based Global Neighbor Inc. (GNI).

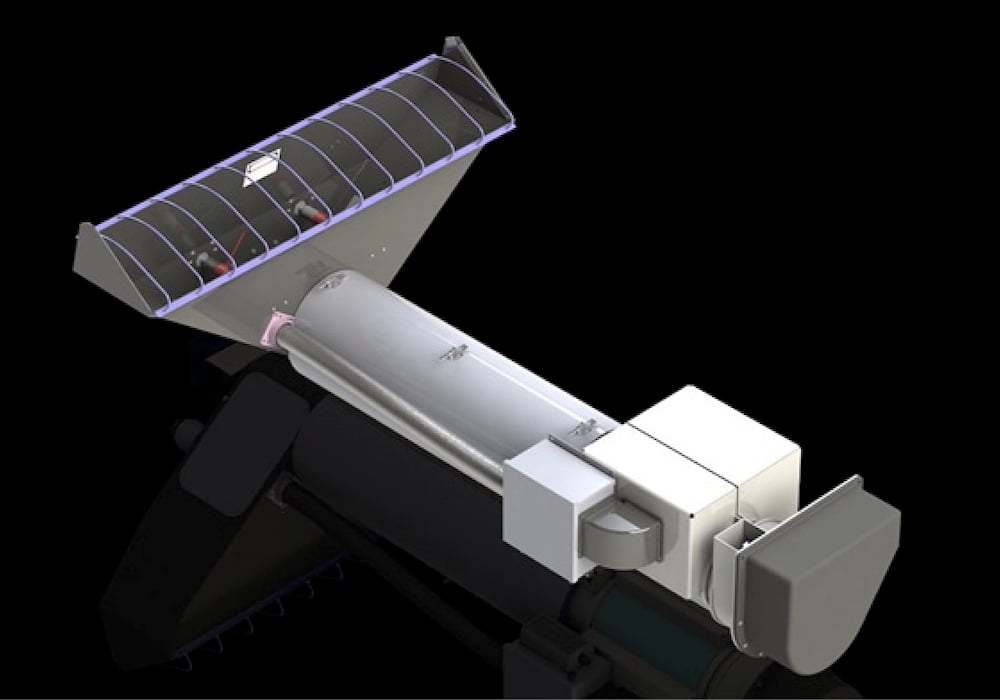

The new concept uses the Dayton, Ohio company’s Directed Energy Flora Control technology, which applies a specific spectrum of light to kill weed seeds coming out of the back of a combine, rather than mechanical destruction.

“The benefit we see for this (GNI system) in the Canadian market is, we get lots of calls from organic growers today who would love to use our mechanical mill to kill weed seeds. This is a huge opportunity to open up the door to those guys.

“They (GNI) have found there’s a certain light spectrum that when you apply it at the right amount of light and certain amount of time, it can kill the seed. If you think about sterilization processes, there’s different ways you can use infrared light. In that context it’s similar. It basically devitalizes the seed. It doesn’t crack it or burn it. It impacts the seed in a way that makes it nonviable.

“Over the last couple of years we’ve been refining it and working with them. The partnership is being announced now. But really, I would say it started two years ago.”

This year there will be two working prototype systems on combines: one in the U.S. and one in Canada.

“We’ve done a couple of prototypes and we’re still working on fine-tuning the exact way that it’s going to mount,” Thiessen says. “We’ll separate the chaff stream, which is where the vast majority of weed seeds are contained, and we’ll direct those into this Global Neighbor device. Once it’s done, we’ll use our chaff-spreading expertise to redistribute that material back into the waste stream of the combine.”

Large seed challenges

One downside is the GNI system is not as effective at killing large seeds, for example with volunteer corn or soybean it would be less effective than on a small mustard seed.

When it comes to applying the GNI system to larger combines, there is just too much material coming through the machine too fast for the current light technology to handle. So the initial model will be designed for use on Class 7 and smaller machines.

“In the early days it won’t be able to handle the volume of seeds from a Class 8 or 9 combine,” says Thiessen of the prototype design. “There’s just too much chaff material coming off the back of these huge shoes.”

It’s possible a hybrid system could be developed later that could make it suitable for the larger combines, but the company will focus on that for future development after the initial light-only design is finalized.

“We have a concept of using a hybridized model where you have a reduced horsepower (SCU) mill and this light technology combining the two,” he adds. “That’s something we’ve been playing around with.

After field trials are complete this season, Thiessen expects to have a limited production release next year.

“We’re hoping to scale up that test into a soft launch in 2025 with kind of a full launch in 2026. If it goes well this year, we should see a number of units on the market in 2025.

“We have an estimate of what we think the retail price will be. We’re hoping it will be about 60 per cent of what our current mill systems are for the bigger combines. That would put it, in Canadian dollars, somewhere in that $60,000 range. We’re hoping maybe even a little better. But there’s a lot to be sorted out on that.”