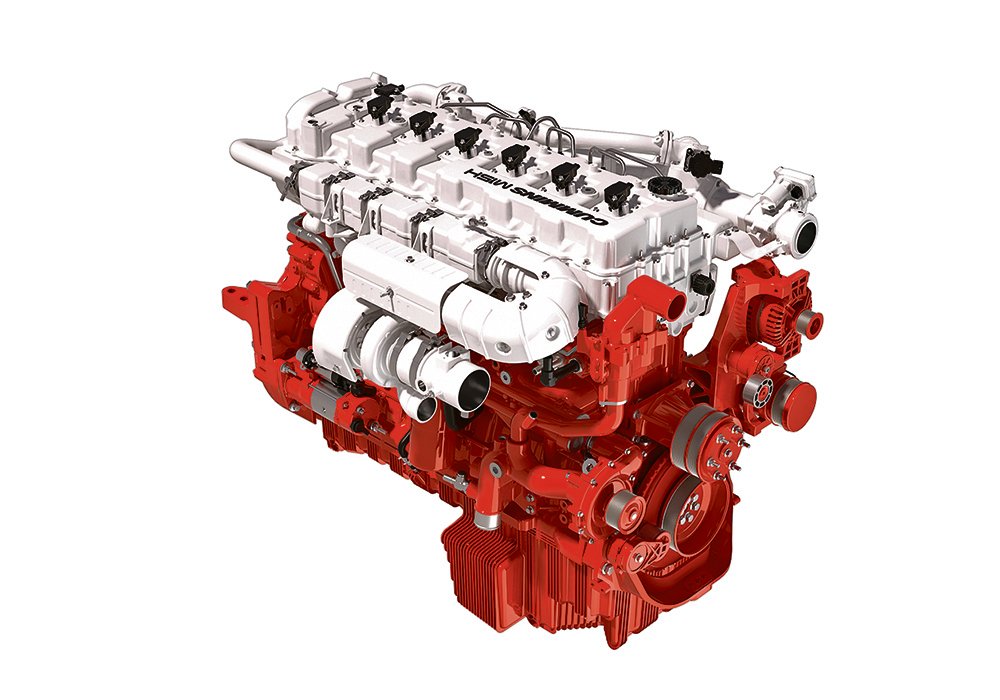

Glacier FarmMedia – The first place farmers will see the 15-litre hydrogen engine being developed by Cummins will likely be in a Versatile tractor.

“We’ve had a partnership with Cummins since the second year we were building tractors,” said Erron Leafloor of Versatile, which makes its tractors in Canada.

“They’ve relied upon us a couple times in the past, most recently with the Tier 4 Final engines, to be their partner and to prove out engine technology in the off-road and agricultural industry.”

Read Also

Evolution of European equipment manufacturers runs deep

A look at how Lemken and Väderstad have evolved from their traditional offerings of tillage equipment to include planting and seeding equipment in their lineups.

Leafloor leads an engineering team at Versatile that’s working on proof of concept for a hydrogen-powered tractor. He said working with Cummins is a good opportunity to prepare for the future.

“I think everybody realizes that diesel engines are going to be a difficult thing to either come by or justify using as we see a more carbon neutral or decarbonized future,” Leafloor said.

Cummins is focusing on 6.7 and 15-litre hydrogen engines. The former is already in prototype and the latter will go to prototype soon.

“Their goal is to have a common engine from the head gasket down across all three of the fuels that they’re planning on making the engine capable of running on, that being diesel, methane and hydrogen,” Leafloor said.

“The concept there is to keep as many parts as possible common. Keep the mounting, the bell housing, and … those kinds of components including the water pump common across all three platforms. They will just change the fuel delivery and exhaust system and probably the turbo charging system that’s associated with each of those three fuels.”

The first Cummins hydrogen engine likely won’t match the horsepower of the 620 Versatile tractors and there are challenges associated with hydrogen power, he added.

“It has a higher jacket temperature so it requires more cooling, for example, and it still requires the capability of having after treatment, though it might be slightly different than what’s used on a diesel engine,” Leafloor said.

“Hydrogen can cause some metals to become brittle if the hydrogen is allowed to enter the grain of the metallic structure. It can cause surface brittleness. So, there’s a lot of research on the engine side just to make sure the components don’t become brittle over time.”

Engineers will have to design high-compression tanks because hydrogen requires a much larger volume to achieve an equivalent amount of power compared to diesel.

When it comes to storing and handling hydrogen safely, Leafloor said he sees parallels with anhydrous, “whether that’s the distribution of anhydrous or the storage of it at retail and on farm, or the understanding of the safety concerns with that type of fertilizer. Not everybody has experience with it and not everybody’s comfortable with it.

“There’s always going to be pockets where this will not be the right technology and there will be progressive pockets that will use this to get a market advantage, perhaps.”

Leafloor said hydrogen engines provide a torque curve similar to diesel engines. Hydrogen engines use a spark plug like a gasoline engine, “which is counterintuitive when you think about a gasoline engine versus a diesel engine, spark versus compressive or compression ignition. We would expect that a spark ignition engine won’t have nearly the torque curve or the torque capabilities, but hydrogen appears to have that capability.”

Hydrogen combustion engines can provide a zero-carbon solution for a high load factor without sacrificing productivity and sustainability programs may consider this.

“Farms that have ties to the major brands, PepsiCo, Walmart, Cargill, that are actively creating partnerships with farms and farmers so that they can advertise that their food is grown in a sustainable method, and they’re willing to pay extra for the certification or the traceability of that sustainable crop,” Leafloor said.

The first prototype is years away and the infrastructure required to support hydrogen tractors has yet to be built.

“The bigger challenge is the logistics and the management of a brand-new fuel type in our tractor. We’ve been used to just pumping diesel fuel out of a tank. Now we must deal with a gaseous fuel that is stored at a very high pressure.”

– This article was originally published at The Western Producer.