Technologies for wrapping, covering and storing corn silage and other forage crops continue to evolve, but efforts to limit the long-term effects of those technologies on the environment haven’t kept pace.

But that hasn’t stopped environmentally conscious stakeholders in the sector from trying to do their part.

Globally, an Israel-based leader in agriculture plastics is developing twine using a proportion of recycled plastic. Nationally, pilot projects are currently underway in numerous jurisdictions for collecting, and hopefully finding, recycling markets for a range of forage handling plastics. Locally, farmers such as Paul Hyatt of Springview Farms Jerseys near Milverton are doing what they can to lessen the chance their crop harvesting and storage practices will contribute to plastics pollution.

Read Also

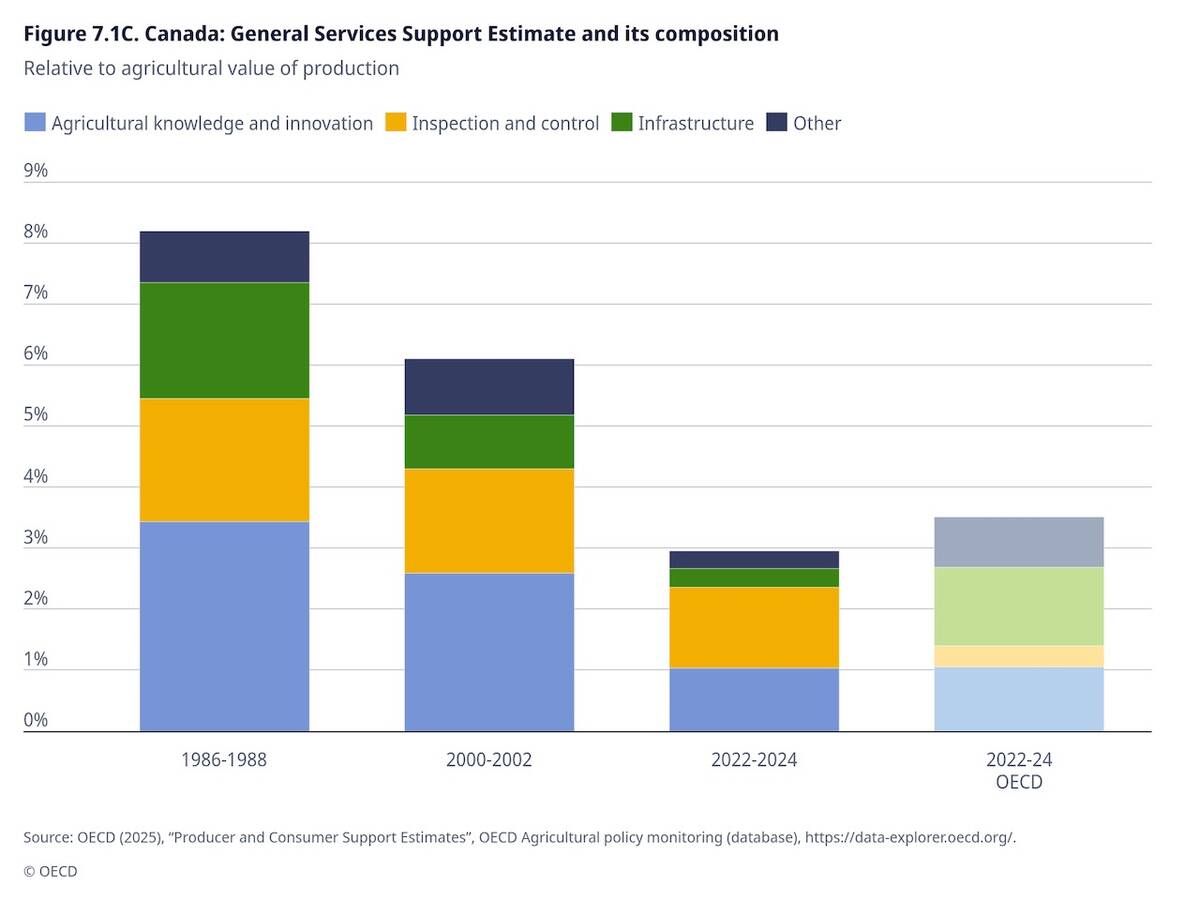

OECD lauds Canada’s low farm subsidies, criticizes supply management

The Organization for Economic Co-operation and Development lauded Canada’s low farm subsidies, criticized supply management in its global survey of farm support programs.

Why it matters: Single-use plastics for forage handling and storage have become much more common on Ontario farms in the past 25 years, increasing farms’ potential long-term impact on the environment.

“The most common practice across the country is to landfill the plastic or discard on the farm,” Cleanfarms, a national not-for-profit organization whose board of directors includes representatives of various agricultural input corporations, said in a news release in June 2021.

Cleanfarms delivers industry-funded and government-funded environmental stewardship programs. Among those programs is a three-year pilot project currently underway in numerous locations across Canada — including Bruce County in Ontario — focused on collecting and finding recycling markets for used silage wrap, bale wrap and plastic bale twine. Funding comes through the federal Agriculture and Agri-Food Canada ministry’s $50.3-million, five-year Canadian Agricultural Strategic Priorities Program (CASPP).

Farmers pick up collection bags, fill them with used ag plastics and deliver them to depots. First there were four sites at municipal waste disposal facilities in Brant, Arran, Eastnor and Greenock; additional depots were subsequently added in Huron Township and Kincardine.

“The objective of our pilot programs is to work with farmers to identify and develop efficient systems to recover these materials so they are recycled, fueling the Canadian circular economy,” Cleanfarms CEO Barry Friesen said in the release.

Contacted by Farmtario in early May, Cleanfarms said it won’t have full details about tonnage of plastics collected in the first year of the Bruce County pilot project until the end of this month. But media spokesperson Barbara McConnell, noting that over 400 bags of material were delivered, said,“we are excited to see what collection figures will be… (and) we are seeing excellent participation from farmers in the area.”

Forage plastics recycling — other than net wrap, which is too contaminated and must be landfilled — has been available for years to some degree in Ontario but has been subject to the whims of the global recycling market. Clinton-based Switch Energy has been collecting, stockpiling and sending out plastics (from farms as well as boat covers from marinas) for recycling for several years, with farmers paying a fee for receiving collection bags and having the material picked up.

Municipal efforts to collect plastics or have them dropped off for recycling have been sporadic, with very little availability in Ontario currently.

But Cleanfarms’ director of stakeholder relations, Kim Timmer, says the agency’s experience collecting and recycling plastic pesticide and fertilizer containers suggests Ontario farmers, on the whole, are eager for access to “convenient (and) cost-effective” ways to lessen their environmental impact.

The pesticide/fertilizer program, which Timmer referred to as Cleanfarms’ “signature program” in Ontario, last year brought in 1.2 million containers for recycling.

“One of the things I’m really drawn to is just the appetite among farmers to have these materials recycled.”

Dairy farmer Paul Hyatt of Milverton is among those. Springview Farms milks approximately 70 Jerseys in a tie-stall and runs about 150 acres owned and rented. He also does custom baling on between 500-600 acres nearby.

Almost a year ago, after posting on social media that he was about to bale some dry first-cut hay, he received a message from his plastic twine supplier. Alain Gratton, Canadian territory manager for Israel-based Tama Plastics, wondered if Hyatt wanted to test out a brand new product for tying his large square bales.

Until now, forage-handling plastics have always used exclusively “virgin” resins, with any products using recycled plastics not able to hold their own in terms of durability or strength. Researchers, including Dr. Erica Pensini at the University of Guelph’s Department of Engineering, have also explored biodegradable, plastic-like resins but those too have so far failed to meet the rigours of on-farm use.

A global leader in forage-handling plastics, Tama recently broke that ‘virgin plastic’ barrier by announcing it now manufactures both twine and net wrap with a proportion of recycled plastic. With the Tama Cycle line of products, the company said it is collecting used twine from farmers and reincorporating it into the production process, which is “an important first step in creating a circular resource loop for crop baling products which collects and reuses spent materials.”

Gratton told Farmtario that Tama has factories in Israel, Hungary, Poland and Vietnam. But the Tama Cycle products — with twine containing 40 per cent recycled plastic and net wrap containing somewhat less – so far represent a very small proportion of the company’s production.

“As this is still a very new process in Europe, our biggest challenge at the moment is sourcing enough consistent-quality PCR (post-consumer recyclable) material that meets the specifications of our standards,” he said. “The small amount of PCR resin being produced is not enough to fulfill Tama’s production capacity. This should improve with time as more programs are set in place.”

Hyatt, who this year is building a concrete slab silo to try and cut back on his need to wrap balage in plastic, agreed to give the Tama Cycle square baler a try. He mad 300 3×3 bales and he is still feeding them out without any problems.

“I wanted to try it out mainly to see if it held up in strength and durability to the regular twine,” he recalled. “I turned the pressure up as high as I could on the baler without breaking any shear bolts and it held up fine.”

He notes the twine, once removed from the bale, acts differently than conventional twine. It kind of falls away from itself, making it more difficult to collect. But Gratton told him it can still be recycled for a second time.

Timmer says Cleanfarms is committed to finding North American markets for the recyclable plastics collected through its programs. “Farmers hold us to that standard; our (board of director) members hold us to that standard,” she said. So sending off the Bruce County ag plastics to one of Tama’s overseas facilities — or to non-agricultural plastics recyclers on other continents — is not likely.

She believes, though, that farmers appreciate this approach because it ultimately cuts back on the environmental impact of having recyclable plastics shipped long distances.

However, she believes Cleanfarms has successfully found North American processors for plastics collected in its more well-established programs — including pesticide containers across Canada and grain bags on the Prairies.

In the short term, the goal of the Bruce County and other pilot projects is to fine-tune the collection, stockpiling and distribution logistics needed to eventually send out bale wrap, silage covers and twine to North American recyclers.

“There is a lot of interest out there in recycled content,” she noted. “Hopefully within a few years, many more Ontario farmers will be able to contribute to that circular economy by conveniently and effectively recycling their plastics.”

Hyatt agrees the recycling side of the equation needs to catch up with the increased use of plastics in farming.

“The weather just doesn’t co-operate to make as much dry hay as we did 25 years ago,” he said. Recycling “is a big thing that our industry needs to look at.”