A Dutch company has a novel suggestion to lower stress in weaned pigs: leave them in the pen where they were born and move the sow instead.

The idea is counter to usual hog production practices in North America, but could limit one of the largest risk periods for young pigs.

Why it matters: The day weaned pigs move to a nursery is one of the most stressful in their lives.

Read Also

Lactanet turns methane expertise into business opportunity

Lactanet’s new fee-for-service breeding tool initiative to reduce greenhouse gas emissions in Canadian and Swiss Holstein herds will launch in April 2026.

Piglets are doubly stressed when moved to a nursery after weaning. They are taken from their mothers, often put onto a truck, then grouped with other piglets in larger groups in a new building or room without the comforts of modern farrowing crates. Then they are expected to eat a new solid feed ration, adapt to it and keep up with their growth.

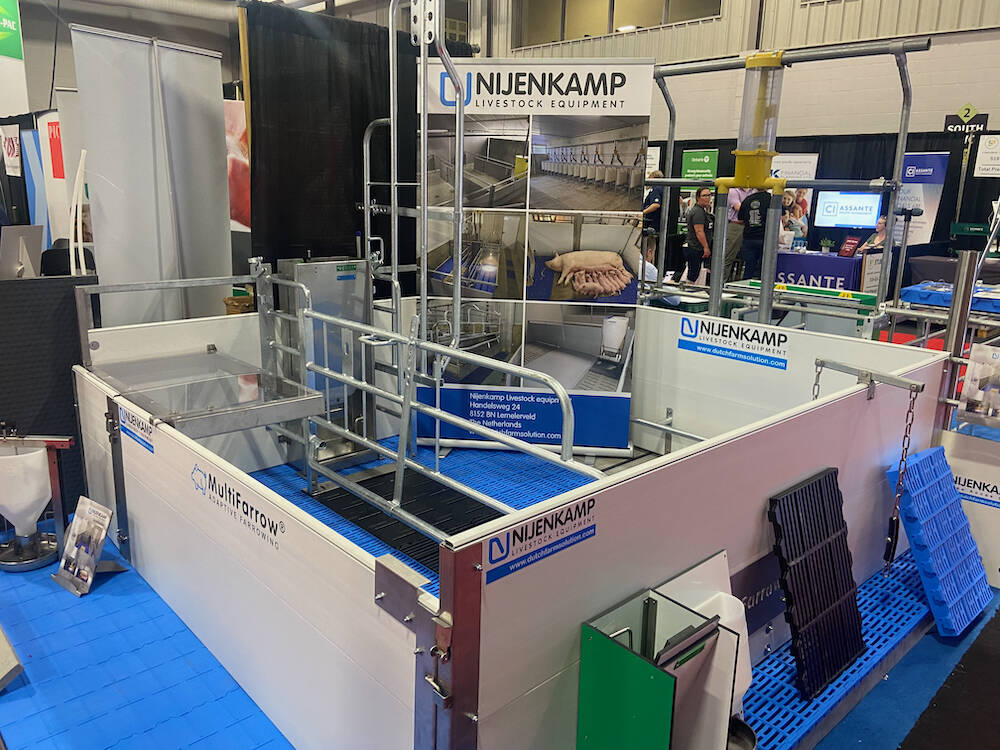

Nijenkamp, a Dutch company, has engineered a farrowing crate with a different approach. In its farrowing stage, a sow can be kept in a crate to protect the piglets as they nurse and grow.

In Europe, there’s increasing demand that sows be able to move free of their crate after six or seven days, says Roy Overesch, who demonstrated the system at the recent Ontario Pork Congress. This system allows that, because the sow crate can be lifted from one end and locked on its other end, freeing space for the piglets and the sow to interact.

There’s lots of flexibility in the system as one arm of the farrowing crate can be left down to give the piglets even more sow-free space. The piglets have a protected area to occupy when they want, with a heating mat or heat lamp. That space in the MultiFarrow system is covered by clear plastic so a farmer can easily see into the sow space.

Bars around the edge of the farrowing crate prevent the sow from lying down right against the wall, so piglets won’t be crushed.

The farrowing room should be kept at about 20 C, says Overesch. At that temperature, the sow is comfortable and piglets do well, but young piglets will also feel cooler and will go back to their heated safe space.

A sow will also put her backside to the warmest place, which Overesch says helps limit piglet crushing problems.

On the designated weaning day, the sow is removed and the piglets have the run of the crate, where they can stay until they reach 10 or 11 weeks, 25 to 30 kilograms or whatever weight the farm sends nursery pigs to a finishing barn. The movement of recently weaned piglets is eliminated.

As for transition to solid feed and water, the MultiFarrow system has a larger and lower wet-dry feeder for the sow that is also accessible by the piglets. This means piglets get a taste of feed and understand the process of moving to solid feed before they are weaned.

“The sow teaches the piglets where to get food,” says Overesch.

The piglets eat sow feed for a time, but at that point it’s about learning where to get feed and water rather than gaining nutrition.

The downside is the need for more farrowing crate systems, which are more expensive than weaning facilities, and sit empty of new births for longer while the piglets reach 25 to 30 kg.

However, the need for a separate weaning facility is eliminated, barns don’t have to be cleaned as often and there’s less labour needed to move the piglets.

Nijenkamp worked with the Brummelhuis hog farm to develop the system, where it was tested for two years. A new barn was then built at the Brummelhuis farm incorporating 242 MultiFarrow farrowing crate systems.