An Ontario sheep producer has built a scalable, sustainable business model for lower-quality wool.

Why it matters: Innovation outside of the textile, yarn and weaving markets can boost farm sustainability, reduce waste, and strengthen Canada’s wool and manufacturing industries.

During the Campaign for Wool Canada’s Spinning Yarns speaker series on Oct. 16, Lindsey Weber explained how she went from sheep farmer to a 100 per cent Canadian wool felt manufacturer in a matter of years.

Read Also

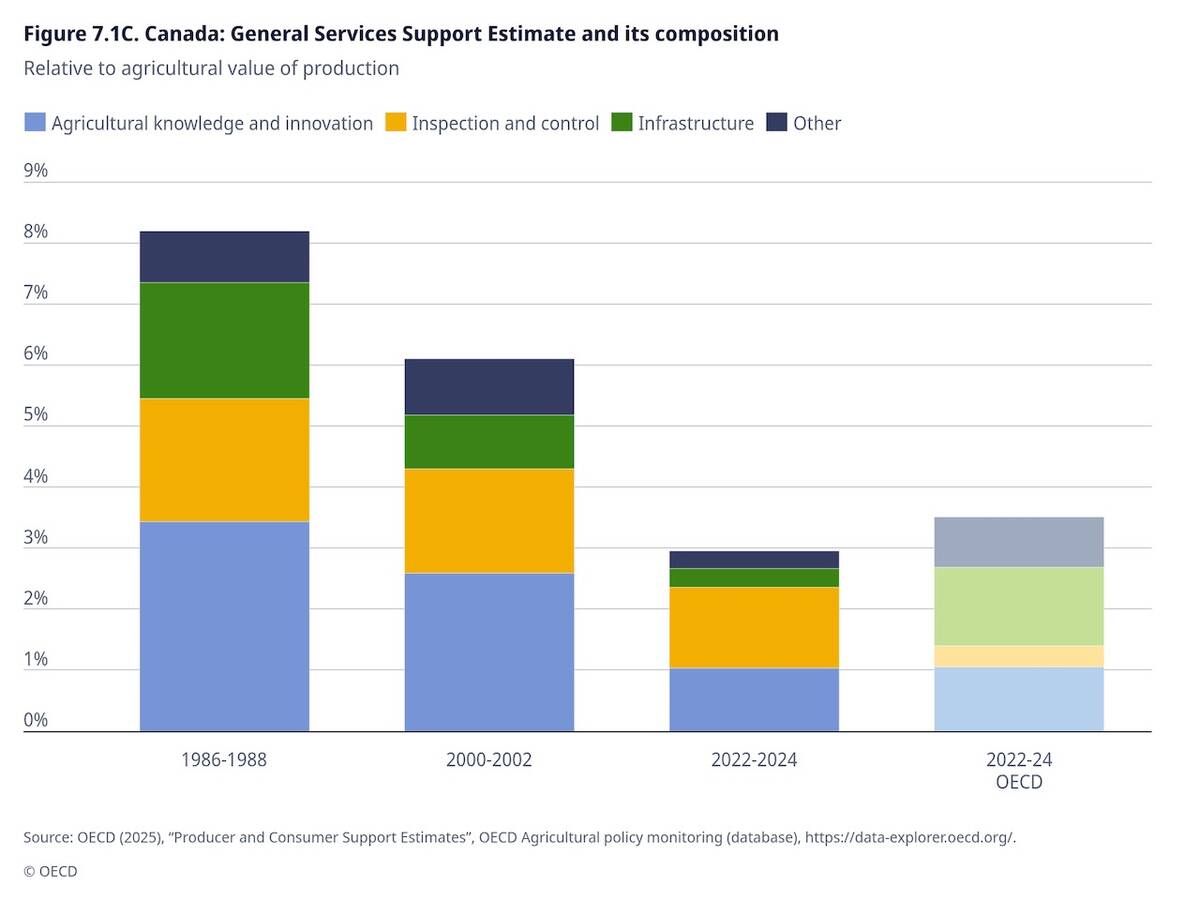

OECD lauds Canada’s low farm subsidies, criticizes supply management

The Organization for Economic Co-operation and Development lauded Canada’s low farm subsidies, criticized supply management in its global survey of farm support programs.

Her geotextile business, WoolGrown, uses wool to create products that amend the soil and help suppress weeds.

Weber has an International Development BA from the University of Guelph with a focus on sustainable local business. She said her grandparents’ farm and her family’s mid-scale manufacturing business fostered her eco-friendly, creative, entrepreneurial spirit.

“I’ve done a lot of research and development work in repurposing and reutilizing materials, especially raw materials, that are in our everyday products,” she said.

“So, when I did get sheep … I started really experimenting and seeing how much you’re able to process, where the wool goes (and) what it’s usually used for.”

From an agri-food byproduct perspective, the fibre quality, length and plant matter contamination level of her wool didn’t fit into the traditional weaving, yarns, textiles, and home goods markets.

Where it did fit was felting.

Weber, an avid gardener and landscaper, began exploring garden fabrics and other home and lifestyle uses for raw wool as a sustainable, regenerative, biodegradable alternative to synthetic materials.

“It’s a natural material,” she said. “It’s biodegradable in nature, has natural moisture retention (and) weed suppression … that’s what sprouted the idea.”

She developed growing pots ideal for transplanting, fibre mats with standard and customizable spacing and hole sizes, sheep tea pouches to enrich water, soil-amending wool pellets and pelletizing services for sheep and alpaca producers.

She even developed a felted lambing jacket.

Weber said their business can access everything necessary to manufacture and transport their products within a 250-kilometre radius, enabling them to increase capacity and volume quickly, whether in felting or pelletizing.

Weber is a prime example of the Canadian Wool Council’s mandate, said Matthew Rowe, Campaign for Wool Canada’s CEO.

“(Our work is) really centred around three main goals: to rebrand and revalue Canadian wool, to connect the entire Canadian wool industry and all levels, and give Canadian wool a voice on the international stage,” he said.

This spring, WoolGrown partnered with the Ecological Farmers Association of Ontario to conduct farmer-led research at a local fruit tree nursery until 2026. The study compares the effectiveness of the wool felt mat, raw wool, wood chips, and a hemp mat. The trial will monitor product degradation and measure soil and plant benefits.

A second trial is comparing WoolGrown fabric to traditional landscape fabrics, with further research planned for 2026 to test the products in real-world conditions, including field, greenhouse, and raised-bed environments. The trial is focusing on biodegradability, durability, and lifespan of the fabrics.

Weber said seeking out wool’s value-added opportunities is an ongoing process, including researching the wool’s keratin potential to replace plastic in everyday household materials.

“That’s really interesting to me from a manufacturing standpoint,” she said. “I don’t have the capacity to look at it right now, but it’s definitely on my radar.”