In an effort to guarantee product longevity across the province, drainage contractors and tile manufacturers are pushing for the adoption of material quality standards for field tile.

Why it matters: Drainage tile that is manufactured using certification standards is less likely to fail prematurely.

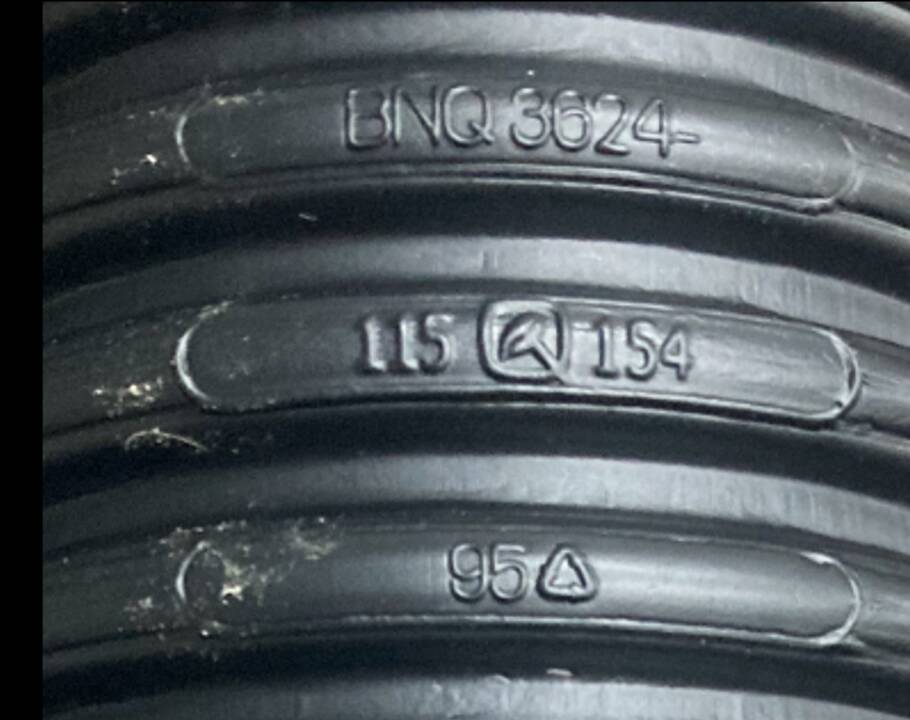

With a number of smaller tile manufacturers opening in recent years, Land Improvement Contractors of Ontario (LICO) is recommending the adoption of two standards — BNQ 3624-115, or ASTM certification — by all drainage tile manufacturers. Mel Luymes, executive director for the organization, said the move comes as landowners and contractors have encountered instances of pipe failures over unexpectedly short periods of time.

Read Also

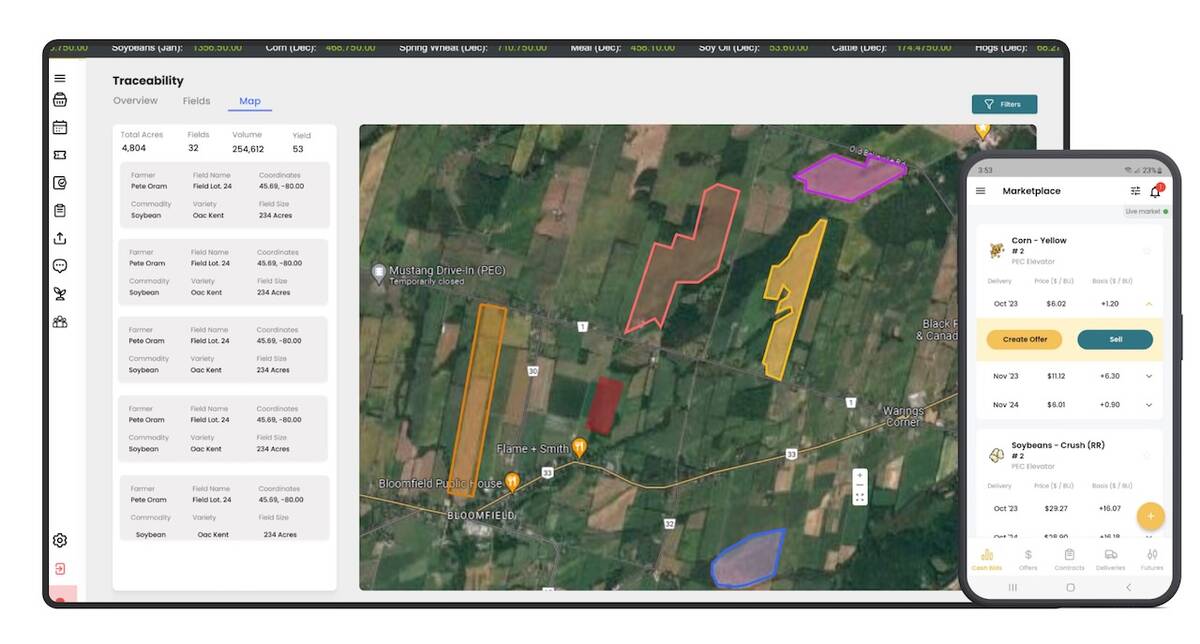

Ontario company Grain Discovery acquired by DTN

Grain Discovery, an Ontario comapny that creates software for the grain value chain, has been acquired by DTN.

“If we say there’s a lifetime warranty, how long is lifetime?” said Luymes. “Lets just have a pre-competitive standard. … It’s in no one’s interest for these pipes to fall apart.”

How tile fails

Drainage tile can fail in three ways:

1. Breaks or cracks resulting from high pressure or acute stress

2. Slow crack growth from longer term but lower threshold stress

3. Chemical failure of the product from UV degradation or oxidization

Breaks from acute stress can happen if tile is not flexible enough to be run through a plough chute during installation, for example. Michael Pluimer, assistant professor in civil engineering at the University of Minnesota, said such “ductile failures” are not common compared to the latter two types of “brittle failures.”

The key to tile longevity depends on the chemical structure of the plastics used in the production of drainage tile, as well as striking a balance between rigidity and flexibility.

“We want high-enough density and you’re going to have a good structural product, but you also want to have enough of these molecules in there that tie things together that prevents what we call stress cracking,” said Pluimer, speaking at the Land Improvement Contractors’ annual conference in January, 2025.

Regarding oxidization and UV degradation, he said the chemical breakdown of pipe material means the tile can crumble under very little or no load well before the end of its intended service life.

“We can make a 100-year material pretty easily,” said Pluimer. “Guess what though — I can also make a five-year material. And we do that by not having them properly stabilized or not having the correct molecules. And they might seem fine from a ductile standpoint, but they’re going to fail in the shorter term if we’re not careful.”

Quality standards lacking

One of the reasons Luymes and LICO have been promoting the adoption of either BNQ or ASTM standards is due to a rise in independent tile manufacturers who lack the analysis capability required to guarantee material quality.

Tony Kime, senior advisor for Soleno and sub-company Bluewater Pipe, said the two standards are a means of managing the types of polymers agricultural tile manufacturers receive — specifically, cheap polyethylene that can sometimes lack the molecules required to ensure longevity in the field.

With the right analysis equipment, manufacturers can determine what needs to be added to a given batch of polyethylene to make it durable. And because the chemical composition of the product manufacturers receive varies considerably, regular testing is necessary.

“If you don’t do that, you’re basically fooling your customers because these are things that won’t be noticed for five, 10, 15 years. … The challenge we have today is there’s a lot of small companies that have started making pipe and they don’t have lab facilities,” said Kime, adding the oxidization of steel as an analogous way to view tile degradation.

Even when tile looks and feels right, that does not mean it will be structurally sound years later.

“Buyers should be asking ‘has the chemical composition of the plastic been tested? Do you know what you made this week was good?’ Right now, a lot of little companies can’t answer that question.”

Kime says the process of meeting the BNQ standard cost Bluewater Pipe about $100,000 per year, including testing, record keeping and the employees required to do the work. Auditors also provide verification annually. The rough cost to acquire the basic equipment necessary to test product is $250,000.

For manufacturers producing significant volume, such costs are manageable. For smaller manufacturers, it’s a greater burden. The costs associated with standards compliance is already built into the pricing of many major tile manufacturers. Non-compliant tile might be marginally cheaper, but he says it’s “buyer beware.”

“A couple pennies in fifteen years may not look so great anymore,” Kime says.

Luymes says much the same, reiterating Ontario-made drainage tile is generally of very good quality — but where poor or questionable quality pipe is available, it “should not be a competitive advantage.”

“We all want to jump together at the same time. We need farmers to start inquiring, then start demanding, because all of us are capable of making certified pipe.”