Managing winter wheat quality prior to harvest can pay dividends.

The Ontario Ministry of Agriculture, Food and Agribusiness offers some best practices in managing fusariam head blight (FHB), or scab, in wheat in an effort to prevent yield loss, reduce mycotoxin contamination and maximize grain quality.

The OMAFA field crop team notes a 2008 report published in the Journal of Plant Pathology found that DON levels increased by 27 to 57 per cent at harvest in wheat that was lodged for just five days before harvest compared to wheat that did not lodge. Additionally, DON levels were even higher in wheat lodged for more than five days before harvest. DON, or deoxynivalenol, is one of the major mycotoxins resulting from fusarium.

Read Also

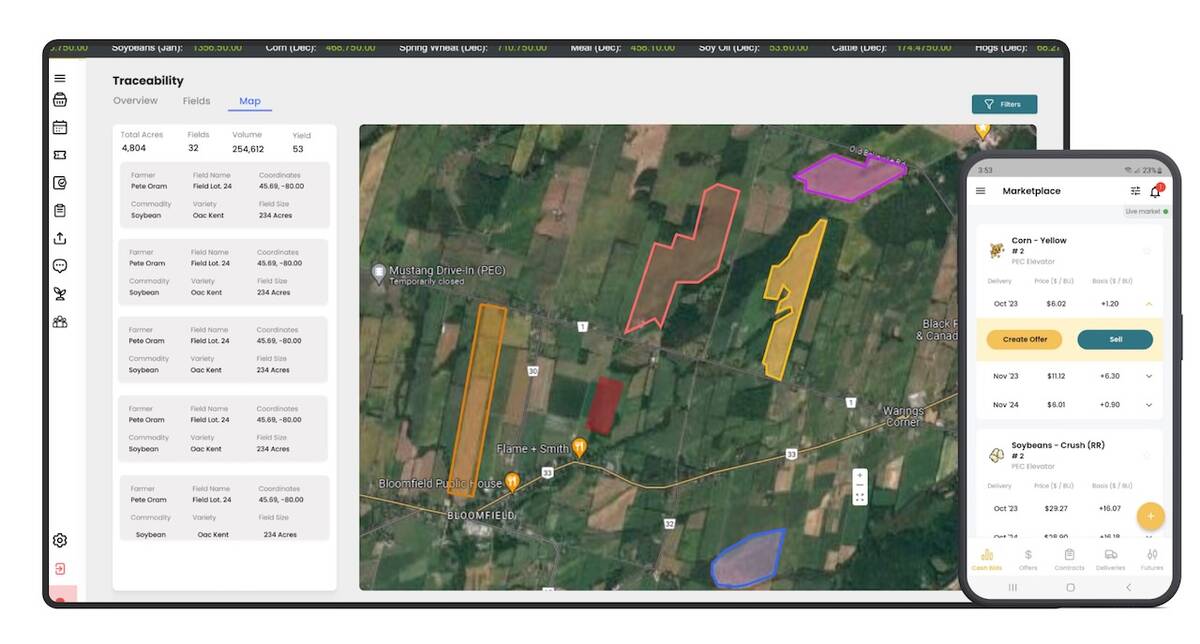

Ontario company Grain Discovery acquired by DTN

Grain Discovery, an Ontario comapny that creates software for the grain value chain, has been acquired by DTN.

Assessing the level of infection in winter wheat fields to help prioritize harvest plans is critical to maximizing quality and minimizing DON.

To conduct an assessment, OMAFA field crop experts suggest blindly grabbing 10 heads and counting the number of heads with any level of infection to give the per cent incidence (e.g., one head out of 10 infected = 10 per cent incidence).

From there, the per cent severity can be estimated by looking at how much of the head is infected (e.g., six spikelets infected out of 22 = 27 per cent severity). The incidence is then multiplied by the severity and is divided by 100 (e.g., 10 x 27 = 270/100 = 2.7 fusarium index).

Repeat this process at 10 locations in the field to arrive at a field-level FHB index. In work revealed at the third International Symposium on Fusarium Head Blight, a fusarium index of 3 could result in DON levels greater than 6 ppm in a high-pressure fusarium year. If fields have an FHB index of greater than 2, they should be prioritized at harvest.

Experts recommend prioritizing fields with high FHB index scores for harvest. Harvest should begin as soon as the combine is able to thresh the crop (even above 20 per cent moisture). Fusarium can continue to grow whenever grain moisture is above 19 per cent. Toxin levels can almost double with one rainstorm.

However one caveat noted by the team is that some combines have difficulty blowing out the lighter fusarium-damaged kernels above 18 per cent moisture, suggesting that growers must then make the call to wait and risk further spread or combine, dry, and remove small kernels with aspiration.

Here are factors to consider when managing fusariam head blight:

Harvest speed: Reducing combine travel speed can reduce fusarium levels. Slower combining speed reduces the amount of material on the cleaning sieve and allows time to separate the good kernels from the infected kernels.

Fan speed: Kernels with initial fusarium infection are small, shrunken and lighter than sound kernels. It is possible to blow a large proportion of these fusarium-damaged kernels out the back of the combine by increasing the fan speed to deliver an air blast above normal ranges.

Testing at Ridgetown College in 1996 found that high fan speeds removed a significant per centage of tombstone kernels caused by primary fusarium infection. Research results showed that there was a tenfold decrease in fusarium-damaged kernels in the grain sample when fan speeds were operated to deliver maximum air blast.

The research recommended starting harvest at maximum cleaning fan speed; however, it also found that it was important to be cautious, as newer combines may blow all the grain out the back.

It is suggested to check both the sample and losses and reduce the fan speed if necessary and again evaluate your harvest sample for fusarium-damaged kernels.

Chaffer setting: Consider adjusting the cleaning sieves (chaffer) to a more wide-open setting. This directs the air blast vertically, slowing the rearward movement of the grain mass and aiding cleaning and separation. Caution must be used to keep wheat heads and straw pieces out of the grain sample if the chaffer is opened.

Dry grain above 16 per cent using heat: According to OMAFA research, fusarium can continue to develop in the grain when moisture is over 19 per cent. Immediate drying of tough grain arrests further fusarium development. Keep in mind baking quality is damaged if the temperature of the grain reaches 60 C (140 F). The kernel temperature of the grain is not the same as the plenum temperature of the dryer. Kernel temperature can be measured by putting a sample of grain in a steel can and placing the thermometer in the centre of the sample. When heated air dryers are used, it is a worthwhile precaution to have samples evaluated to ensure the dried grain meets market standards.

Pre-harvest sprouting can be a concern if persistent rainfall events continue through to maturity and beyond. Pre-harvest sprouting can result in downgraded wheat at the elevator due to a low falling number. Additionally, pre-harvest sprouting can be initiated by cool, rainy conditions once wheat has reached physiological maturity.

When there are multiple rain delays, there is an even greater risk for sprouting, even for varieties with good sprouting resistance. Hard red wheat is generally more tolerant to pre-harvest sprouts, while soft white wheat is extremely vulnerable.

Previous Ontario research showed that when harvest was delayed by two weeks, the amount of sprouted wheat increased by almost 10 per cent and yield was reduced by almost 4 bu./acre. In 2021, many areas received persistent rainfall once wheat reached physiological maturity, resulting in increased sprouts and low falling numbers across the province.

Low falling numbers can also be caused by late maturity alpha-amylase (LMA) production. LMA production is triggered by cold or heat shock during the later stages of maturity (26 to 30 days after pollen shedding). However, the specific temperature swing needed to induce LMA is not known.

Wheat is considered sound and satisfactory for most milling and baking processes with a falling number of about 300 seconds, according to research; however, levels as low as 250 can be acceptable to end users. While growers are given a grade based on sprouts, mills are increasingly looking at falling numbers as an indicator of wheat quality. As a result, growers are encouraged to review all contracts to ensure they are aware of falling numbers or any other quality requirements upon delivery of grain.

Experts suggest that the best defence against sprouting and low falling numbers is to harvest wheat as quickly as possible once it reaches maturity.

Doing this, paired with drying your grain, is the most effective means of avoiding sprouting. Selecting pre-harvest sprouting-resistant wheat varieties can also help reduce risks.

Protecting financial interests is also important, with experts recommending farmers ensure their production insurance, which may compensate affected winter wheat growers by applying a quality factor to low-grade wheat yields to reflect the lower prices received for these crops, is up to date to reflect farm operations.