[Updated April 4, 2025] – Four stand-out innovations grabbed the attention of Canadian beef farmers at EuroTier 2024, the world’s largest trade fair for livestock production, in Hanover, Germany on Nov. 15 to 18, 2024.

The first two – an autonomous mixer wagon and an automatic bale spreader – fall neatly into the ‘nice-to-have’ category, their main benefits being they save on labour and boost efficiency.

Arguably, the safety-enhancing features of the latter two – a cattle crush with advanced safety systems and a bale transport trailer with a patented cargo securing system – put them squarely in the must-have category.

Read Also

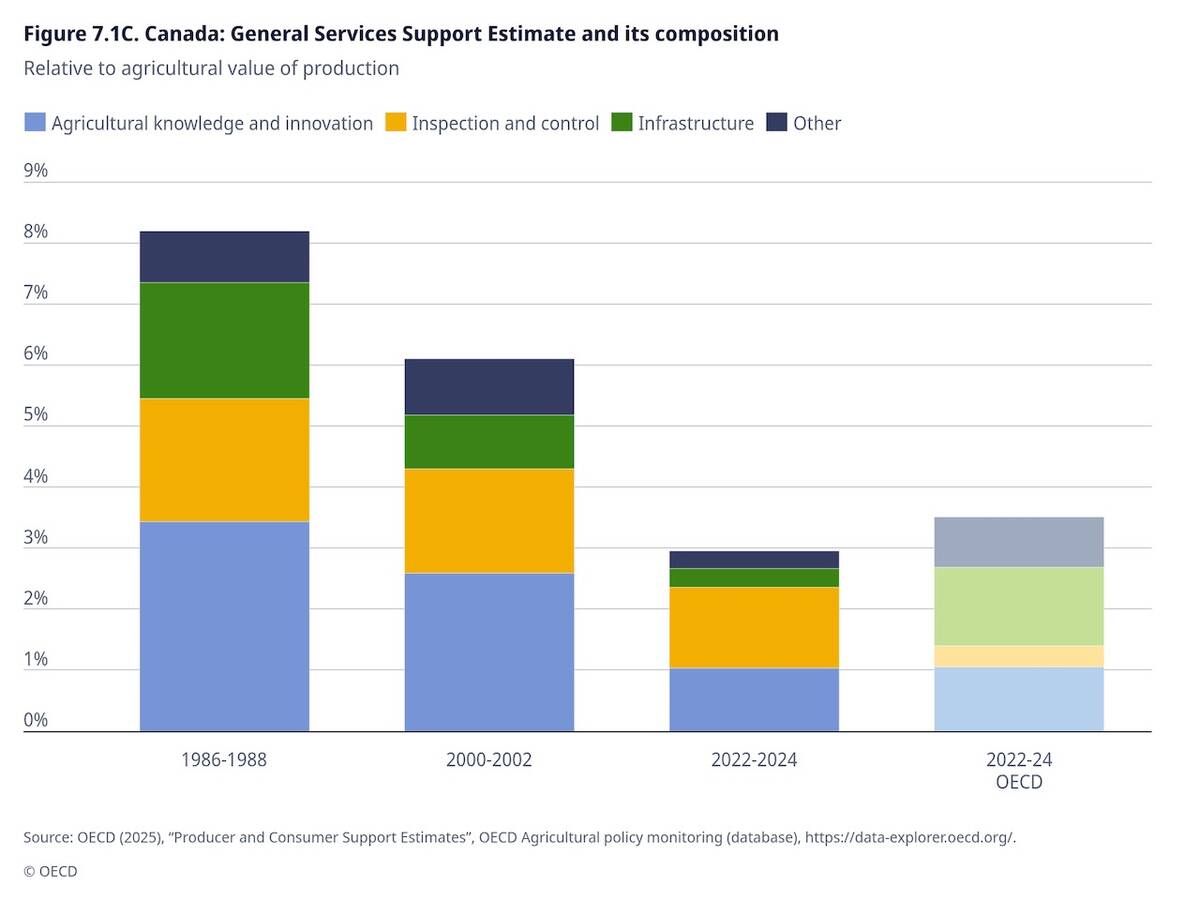

OECD lauds Canada’s low farm subsidies, criticizes supply management

The Organization for Economic Co-operation and Development lauded Canada’s low farm subsidies, criticized supply management in its global survey of farm support programs.

Alberta beef producer Graeme Finn visited EuroTier and offered input on what makes each product innovative.

Kuhn launches autonomous mixer wagon internationally

AURA, Kuhn’s autonomous mixer wagon, first hit the market in France in 2022. AURA is designed to load and distribute feed autonomously, reducing daily feeding time from hours to minutes. The only manual labour involved is the removal of the bunker cover. From time to time, the sides of the silage will need to be removed manually as well.

When asked what sets Kuhn’s autonomous wagon apart from its competitors, Vincent Müller, head of marketing at Kuhn Germany, pointed to the milling head.

“Our competitors’ products can’t load themselves; they don’t have the milling head,” he said. “The milling head is very innovative for this machine.”

Milling silage as it loads means it’s no longer necessary to grind larger chunks of forage in the tub, which in turn lowers power requirements. AURA operates efficiently on a 57-horsepower diesel engine, and consumes about 3.5 litres of diesel per hour. As it has a 180-litre diesel tank, the autonomous unit has the ability to work continuously without topping up the fuel tank for 50 hours.

Finn saw Aura displayed at EuroTier and was greatly impressed by the technology.

“Definitely 100 per cent for the dairy [operation] it’s really slick,” he said. “It will cut down on the dairyman’s time, especially with this new one that’s self-loading.”

“For feedlots, it would take a little bit more finessing,” he said, adding that a bigger version of Aura with more power would be better suited to large-scale operations.

AURA includes a digital platform for easy programming and monitoring that sends an alert if an obstacle is detected, ensuring safety without constant interruption.

The autonomous wagon is suitable for farms with 80 to 280 cows. It is not currently available in North America.*

Spread-a-bale cuts bedding time, improves air quality

Now-retired dairy farmer Michael Hughes, who lives in the United Kingdom, spent years looking for a way to simplify the arduous task of spreading bedding in pens. His solution, Spread-a-bale, has been on the U.K. market since 2005, but was showcased at EuroTier for the first time in November.

The machine, which comes in a variety of models and can be mounted to a skid steer front-end loader or industrial loader, can spread straw bales in 45 seconds without generating dust.

Hughes said the machine reduces labour by 75 per cent, and improves straw use efficiency by 50 per cent. It is suitable for both round and rectangular bales, and is able to spread a 25-foot wide layer. Unlike competitors’ turbine machines, it doesn’t use pneumatic forces, making it faster and more energy-efficient.

According to Hughes, the once-onerous task is completed in four simple steps: attach the unit, load the bales, de-twine and spread.

“The hardest job is cutting the strings,” he said.

Spread-a-bale isn’t available in the North American market yet, but Hughes is actively looking for distributors.

Finn spent some time at the Spread-a-bale stand while at EuroTier. He was impressed by Hughes’ attention to detail.

“He’s put a lot of thought into this,” he said. “The simplicity of it, that’s what really cranked my handle.”

Clipex cattle crush boosts handler safety, safeguards cattle

Working with cattle always involves some level of risk, but a well-designed and well-built handling system can minimize risk for both handler and livestock. The Clipex HD2000 cattle crush, which uses innovative pneumatic technology, is designed to do just that.

Unlike hydraulic systems, which can continue applying force and potentially harm the animal, the HD2000 uses air-operated mechanisms that stop when resistance is met.

“The likelihood of you damaging, or breaking a leg, or squeezing an animal ‘til it collapses, is less of a possibility with the air-operated system,” said Rosie Anglim, sales manager at Clipex.

Key safety features include a head scoop that secures the animal’s head without excessive pressure, which reduces injury risk for both handler and livestock. The anti-bruise oval rail design minimizes bruising by preventing concentrated pressure points. Additionally, the built-in vet section allows handlers to work safely behind the animal without risk of being kicked.

The automatic weighing and drafting system further streamlines operations, allowing farmers to process up to 300 cattle per hour with minimal stress on the animals.

“As soon as the weight is registered, the door automatically opens, and the draft is set up before the door opens, so they run out smoothly,” Anglim said.

Collectively, these features enhance efficiency while ensuring a low-stress environment for both cattle and handlers, noted Finn.

“They’re really taking into consideration the animal welfare on this piece of equipment and human welfare,” he said. “When I looked down the barrel of that squeeze the other day, I loved how it was so smooth and nothing was jutting out at you.”

While Finn loved the design, he’s concerned that pneumatic technology could prove unreliable under extreme cold conditions.

“You’d have to have a dehumidifier on your air lines because in the wintertime here the lines would fill with ice and then air wouldn’t flow,” he said. “So it’d have to be hydraulic in Canada.”

Oehler patented hay cart prioritizes safety

Designed to improve efficiency and safety during the transport of hay or wood, Oehler’s innovative hay cart features a patented hydraulic securing system that eliminates the need for manual strapping.

“You pull on a lever, the hydraulic system lifts up the rails, and everything is fixed,” explained Nico Schwendemann, general manager of sales at Oehler.

Not only does Oehler’s system save significant time, but it also reduces the risk of accidents.

The hay cart is also built with durability and flexibility in mind. It features a reinforced trailer platform for added stiffness. The trailer accommodates different types of loads as well. Users can choose hydraulic walls on one or both sides depending on their loading and unloading needs.

“If you want to be more flexible, then you choose both sides,” Schwendemann noted.

He added that Oehler also prioritizes longevity. High-quality coatings prevent rust and the company works to ensure spare parts remain available long-term. The company sees international potential for its hay cart and is exploring markets in North America.

“Maybe I will go in February to the U.S. to visit some fairs,” Schwendemann said.

Finn knows firsthand what happens when hay bales aren’t properly secured. He was hauling a load road with his brother-in-law when a bale fell off and hit a vehicle behind the trailer. Luckily, no one was hurt – and it was his sister-in-law driving the vehicle.

Part of the problem is that securing bales is a slow-going, tough job, and often drivers don’t have far to travel.

“You have to have every bale strapped and that takes time,” he said. “Trying to throw those straps over and get them right centre on top of the bale takes forever. It’s a bloody big on show.”

Although the design of Oehler’s trailer eliminates the needs for straps entirely, it’s uncertain whether or not this would be permissible under Canada’s Traffic Safety Act.

Regardless, the trailer isn’t available in Canada yet, and as Finn sees it, it still has one drawback: it’s not self-loading.

“If it was self-loading, they would sell hundreds of them over here,” he said.

Eurotier will take place again in Hanover from Nov. 10 to 13, 2026.

*UPDATE: A previous version of this article incorrectly stated that the AURA was available in Canada. It is not. We apologize for any confusion that this caused.