Stacy Frey received some sage advice while surveying the smoky remains of the Adieu Farm dairy barn fire on July 31, 2020.

“My brother-in-law said, ‘you know, a year from now, you’ll be happy. It’s the year in between – all the planning and clean-up and everything (that’s tough)’,” said Frey. “It’s definitely true. Now that we’re up and running again with this facility, it feels good and normal again.”

Read Also

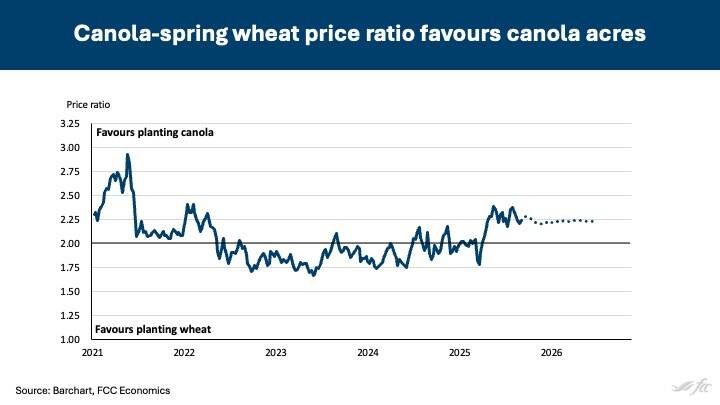

Livestock leads Canada’s farm economic outlook

Canadian grain farmers are being warned to brace for a profit crunch this year with low commodity prices and high input costs.

The Freys encountered a four-month delay in acquiring the needed permits and scouting a new location on the farm after discovering the original site was too close to town for the setbacks. Shovels were in the ground by December 2020, and Frey said the cows returned to the farm for milking on Oct. 12, 2021.

While the family is grateful for the 45,168 square foot modern dairy barn, Frey wishes it didn’t require a devastating fire to get there.

“The barn was getting old. How much longer it would have lasted, we don’t know. We were maxed out with how many cows you could milk already,” he said. “So in that aspect, we can grow moving forward (but) we had no plans of building. It forced us into a new barn.”

He said all the cows milking in the new facility were at the old barn as heifers or milking cows on pasture when the fire began, keeping losses to approximately 20 calves.

Within 15 minutes of the blaze starting, Merle, Frey’s father, called Dennis Martin, a Palmerston-area dairy farmer, and asked if he had room to take the cows. Martin had recently sold some of his herd and could accommodate all of Frey’s.

“That was the biggest relief when I knew he would take them because it (the fire) happened at 3:30 p.m., and they had to be milked at six,” said Merle Frey.

Several farmers offered to take the cows, said Merle, but Dairy Farmers of Ontario prefers a milking herd to be in one spot.

Stacy Frey said the surviving young stock went to another farmer, and the two operations worked together through the year to ensure heifers got to the milking barn after calving.

The former tie-stall cows trained on a parlour system while at Martin’s, so entry into the GEA Global 90i, replete with a 16-cow, parallel parlour, Dematron 70 milk meters in medallion cabinets paired with IQ milkers, was virtually seamless, said Frey.

“It wasn’t a lot of adjusting for them, just new and different,” Frey said. “They picked it up pretty good.”

Dave Kabbes, Conestogo Agri Systems dairy equipment salesperson, said the Global 90i parlour system has individual indexing, which positions the cow back to the butt pan for easy access for the operator and allows for group or individual release.

“We can let one cow go, if need be, for special treatment,” Kabbes explained. “There’s a nice exit area so they all can leave at once, and then (the farmer) can lower the gates down, and the next group can start coming in.”

The holding area is sloped to encourage cows to move toward the parlour, allows for easy group separation and a crowd gate encourages forward cow movement.

“As the cows come in, there’s a committal area, so only one cow comes in at a time, so there’s no traffic jamming,” Kabbes added.

The parlour’s IQ milker unit, unique to Conestogo Agri Systems, has no vacuum on the liner until the teat goes in, said Kabbes.

“It makes for quiet operation and is very comfortable for the cow. This is designed for throughput and efficiency with just one person.”

But for the Freys, it easily accommodates farm kids that want to help or a husband-and-wife team.

Frey is excited about milk production data being captured in the new parlour, along with rumination and heat cycles. He is learning how to use the information to maximize the operation.

The new facility is expandable if his children decide to carry on with the family farm.

The Freys have milked approximately 60 cows for the last 50 years. However, the new facility could accommodate more than 190 cows by transforming the heifer area into a milking one.

“You could potentially build a heifer and dry cow barn for the future,” he said.

The main barn features Canarm free stalls, self-lock and gates, Legend rubber soft mats, GEA Houle alley scrapers and manure handling, Ventec cyclone fans, flap duct ventilation and Polymat Air Curtains.

There’s also an isolated calf room with Canarm comfy calf suites.

“The biggest labour savings is manuring out,” said Frey. “Now we can pull partitions and use a loader bucket and clean out the pens rather than forking it out by hand like we used to.”

Feeding and bedding are machine-driven, not pitchfork reliant, which is a time saver and a back saver. And the animals can walk around.

“We don’t have to tie them up every day at noon,” he said, adding that once they finalize landscaping and fencing, the cows and heifers will have pasture access.

While there are labour savings and a degree of automation, Frey said there are still plenty of manual chores for his kids and his dad to keep busy.

“We think it’s good to be in the barn to see things that (being) automated won’t see,” he said. “But it’s set up so we could go automated in the future with feed pushers.”

Dale Martin, retired Woolwich Township Fire Chief, spent a lot of time in the old barn when his uncle, Merle’s dad, ran the farm.

“It was a barn that stood out in the community,” said Martin. “Driving on the highway, you’d always see the red barn, and I think a lot of people miss that, what the landscape did look like, but this is a very nice barn too.”

More than 1,000 people made their way through the Adieu Farm’s doors during the St. Patrick’s Day open house to celebrate the return of the dairy cows and the Frey’s rise from the ashes.

While the fire was life-changing for the family, Martin said it’s a comfort to know the new barn is safer regarding fire hazards and will allow them to continue with a dairy farm tradition.

“Here everything is separated. You don’t have all the fire load in the building, with hay and straw and that type of thing,” he said. “It was a pretty tough fire to put out. Here you have half a chance of knocking it down.”