A challenge this harvest season will be dealing with variable grain moistures from field to field as well as within individual fields. Additionally, drought conditions that have persisted and rapid accumulation of growing degree days are leading to grain that can quickly became overly dry.

Follow the below set of tips to limit yield loss this fall.

Fields with poor stalk quality first

Standability of corn stalks could be a concern this fall. In fields with lodging, make appropriate harvest adjustments, especially to the combine header, to better pick up those stalks.

Adjust combine settings more frequently as conditions change within fields.

Inspect combine parts and repair or replace any worn or damaged parts, and take the time to check that all sensors are working.

Combine head adjustments

For corn, set the deck plates so they are tapered from front to back, with 1/8-inch less gap between the plates at the leading edge than at the back. With adjustable deck plates, set them initially using the operating manual and then adjust based on stalk node size so that there is a small gap between stalks and plates.

Ideally, the gap between the plates should be narrow enough to avoid shelling kernels, but not so narrow as to cause stalk wedging or pushing over stalks. Reducing header speed can also reduce butt shelling kernels.

For soybean, prevent gathering losses by ensuring the cutterbar condition is good and knife sections and ledger plates are sharp. Soybeans will likely be brittle this year as the likelihood of excessively dry beans is high. If shatter losses are high, try reducing the reel speed, but not so much that stalks begin to drop.

Lower reel height when plant height is short, but the minimum should be set so there is always at least a two-inch gap between the reel finger tips and the flexible cutter bar with the bar at its highest position.

Threshing and separation unit adjustments

Overly dry grain is brittle and more susceptible to breaking; the threshing system is the primary risk for breakage. Adjust the clearance between the rotor and the concave to reduce damage by narrowing or widening it in increments until it is narrow enough to thresh out the grain while minimizing damage.

Because threshing of drier corn is easier, you may be able to adjust settings to be less aggressive and still get efficient threshing. Decrease rotor speed as beans become drier.

Fan speed and sieve adjustments

Obtaining good separation between the grain and chaff in the cleaning shoe is a function of the cleaning fan air speed and sieve adjustments. When making pre-harvest adjustments, ensure the cleaning fan is functioning well at different speeds. The intent is to be able to match air speed with the crop throughput coming into the cleaning shoe for separation during harvest.

Also, ensure that airflow across the cleaning shoe is as uniform as possible for all fan speeds. Sieve adjustments will depend on the kernel sizes passing through the cleaning shoe during harvest.

Smaller soybean or corn kernels require narrower sieve openings; however, this can increase the number of larger kernels going back to the threshing unit as part of the tailings.

Check combine adjustments

Once well within a field and away from the field edges, stop the combine, back up 15-20 feet, and get out to measure harvest losses. Systematically measure losses to determine if losses are occurring at the header or are going out the back of the combine due to poor threshing and separating.

If ear losses are high, also check for ears dropped from the stalk before harvesting to know what your pre-harvest yield loss is.

Core it, cool it, check it.

Overly dry grain can lead to more dust, fines, and mould, so if you aren’t cleaning grain before storing it or spreading grain into the bin, be sure to remove the central core of poorer quality grain before long term storage.

It may be necessary to core multiple times as the bin is getting filled.

Record quality factors for the grain in each bin, including moisture content, presence of fines and broken grain, and the test weight, but be aware that test weight might be deceptive due to presence of small kernels. If this is the case, use test weight as an indicator of quality and storability cautiously.

Don’t reduce good grain’s quality for storage by mixing with poorer grain. Market off the lowest quality grain first.

This article is adapted from an original article published by Iowa State University Extension and Outreach.

Read Also

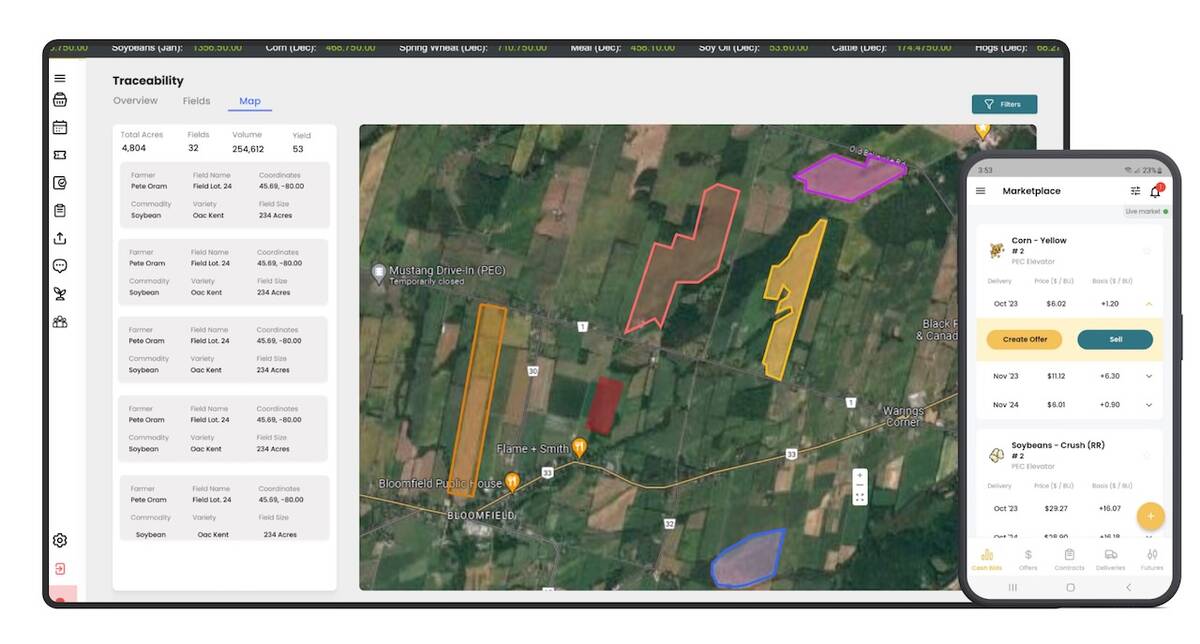

Ontario company Grain Discovery acquired by DTN

Grain Discovery, an Ontario comapny that creates software for the grain value chain, has been acquired by DTN.