A new University of Guelph project aims to develop safe-rate guidelines for common strip till fertilizer placements.

There is limited guidance available now for safe fertilizer rates for strip tillage. Unlike 2 x 2-inch planter banding, there are many different fertilizer placement options for strip till, which likely leads to tradeoffs with fertilizer placement. Although placement with strip till is closer to the seed and likely improves starter fertilizer effect and efficiency, risks to the crop and soil are increased if too much is applied.

One of the most common strip till questions is about safe rate. Maximizing rates may improve logistical efficiencies, maximize yield responses and possibly reduce need for other in-crop or broadcast applications. However, at some point crop safety becomes a concern.

Read Also

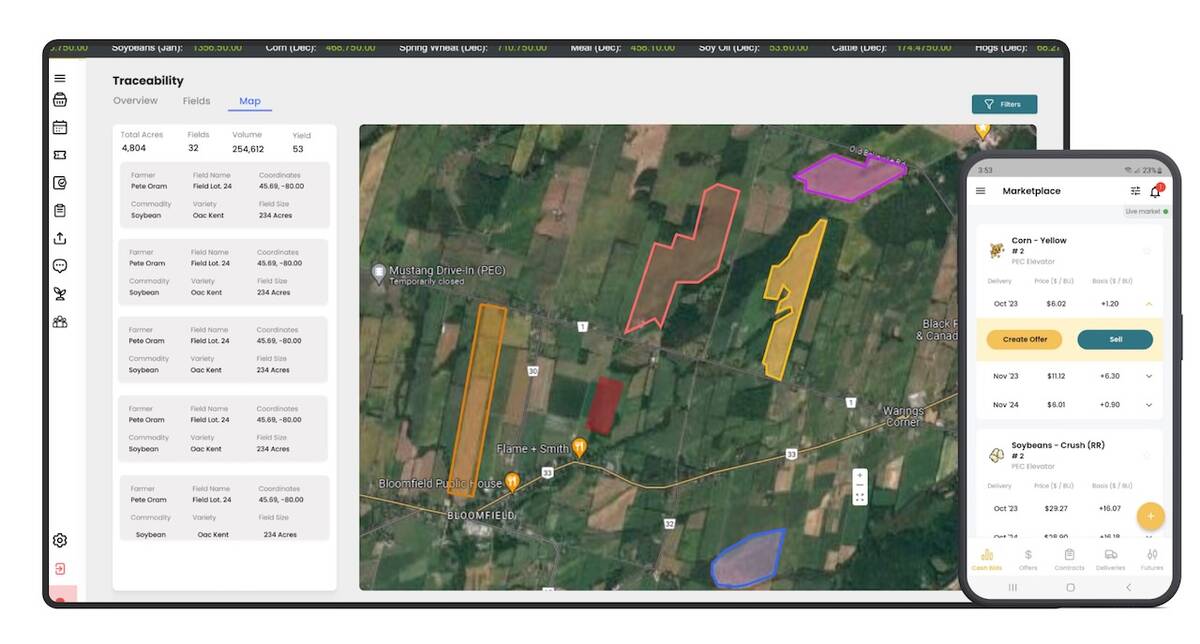

Ontario company Grain Discovery acquired by DTN

Grain Discovery, an Ontario comapny that creates software for the grain value chain, has been acquired by DTN.

[RELATED] Strip till a matter of helping the soil and lowering costs

Ontario has safe fertilizer rates for in-furrow and 2 x 2-inch planter banding, but unlike these placements, strip till fertilizer placement can vary significantly across and even within strip tiller types.

For example, some coulter strip tillers mix fertilizer throughout the strips, while some shank-style strip tillers band fertilizer behind the shank. Some may be six inches deep, others four inches, in attempts to get starter fertilizer effect.

There is a tradeoff with fertilizer placement in the strip:

- Closer to the seed, the benefit from starter fertilizer may be increased, but crop injury will be seen sooner if rates are increased.

- Increased separation between seed and fertilizer gains crop safety but may reduce starter fertilizer effect.

Fertilizer placement project

To build data to assist in safe-rate decisions, a new University of Guelph project has started with soil fertility and nutrient management professor John Lauzon. Funding is provided by Grain Farmers of Ontario and the Canadian Agricultural Partnership.

[RELATED] VIDEO: Finding efficiencies in fertilizer applications

A custom-built four-row strip tiller is being used to investigate four strip placements that may reflect more common fertilizer placements used by strip tillers:

- Fertilizer released at a four-inch depth behind shank in efforts to get starter fertilizer effect, but possibly at a higher risk for fertilizer injury.

- Fertilizer banded at the edges of the strips. While not common among commercial units, some Ontario growers have custom-built strip tillers to deliver fertilizer on the strip edges with the idea of keeping fertilizer out of the seed zone for safety while having it in a place for starter fertilizer effect.

- Fertilizer released at six-inch depth behind shank, reflecting where fertilizer is placed more deeply to avoid safety risks but possibly at the expense of starter fertilizer effect.

- Fertilizer mixed throughout strip with either a shank or coulter strip till unit, avoiding concentrations of fertilizer.

Safe rates for various placements will depend on the fertilizer being used. To cover more common fertilizer scenarios among strip tillers, the project will look at safe rates of:

- Fall potash: Are there residual risks to higher fall potash rates, particularly in very low testing fields where a grower would like to build and apply higher rates through a fall application?

- Spring urea, where a grower would like to only apply N in the spring strip, representing a scenario where P and K were applied in fall or needs were met in other ways such as manure.

- Spring balanced NPK blend (urea + MAP + potash, e.g. 19-19-19), to represent scenarios where growers will apply P and K in the spring strip, but also want to include a reasonable amount of N in the same pass.

- Spring balanced PK blend (MAP + potash, e.g. 5-27-27), to represent scenarios where growers will apply P and K in the spring strip, but most N is applied outside the strip, such as a top-dress or side-dress application.

Soil texture affects crop safety, so trials are conducted on clay-loam, loam and sand-type soils. Populations, emergence timing and crop stage variability are being recorded as measures of fertilizer injury.

Beyond safe rates, these treatments may also shed light on which of these fertilizer placements is more efficient for yield response.

Overall, there likely isn’t one perfect placement in the strip. Optimum placement likely depends on the goal of the system (starter response, crop safety), and is likely a function of any single producer’s soil tests, needs for starter fertilizer effect, desired fertilizer rates and logistics.

– This article originally appeared in Field Crop News.